1. Introduction Laser cleaning is a non-contact surface treatment technology that utilizes high-energy laser beams to act on material surfaces, causing contaminants, deposits, or coatings to vaporize, delaminate, or undergo photochemical decompositio...

VIEW MORE

In industrial manufacturing, equipment maintenance, and surface treatment fields, the removal quality of surface contamination directly affects subsequent processing, assembly precision, and service life of workpieces. As environmental regulations ti...

VIEW MORE

I. Introduction Laser welding technology is widely used in lithium battery sealing, consumer electronics, medical device manufacturing, and metal processing due to its high energy density, welding precision, and low deformation. However, during long-...

VIEW MORE

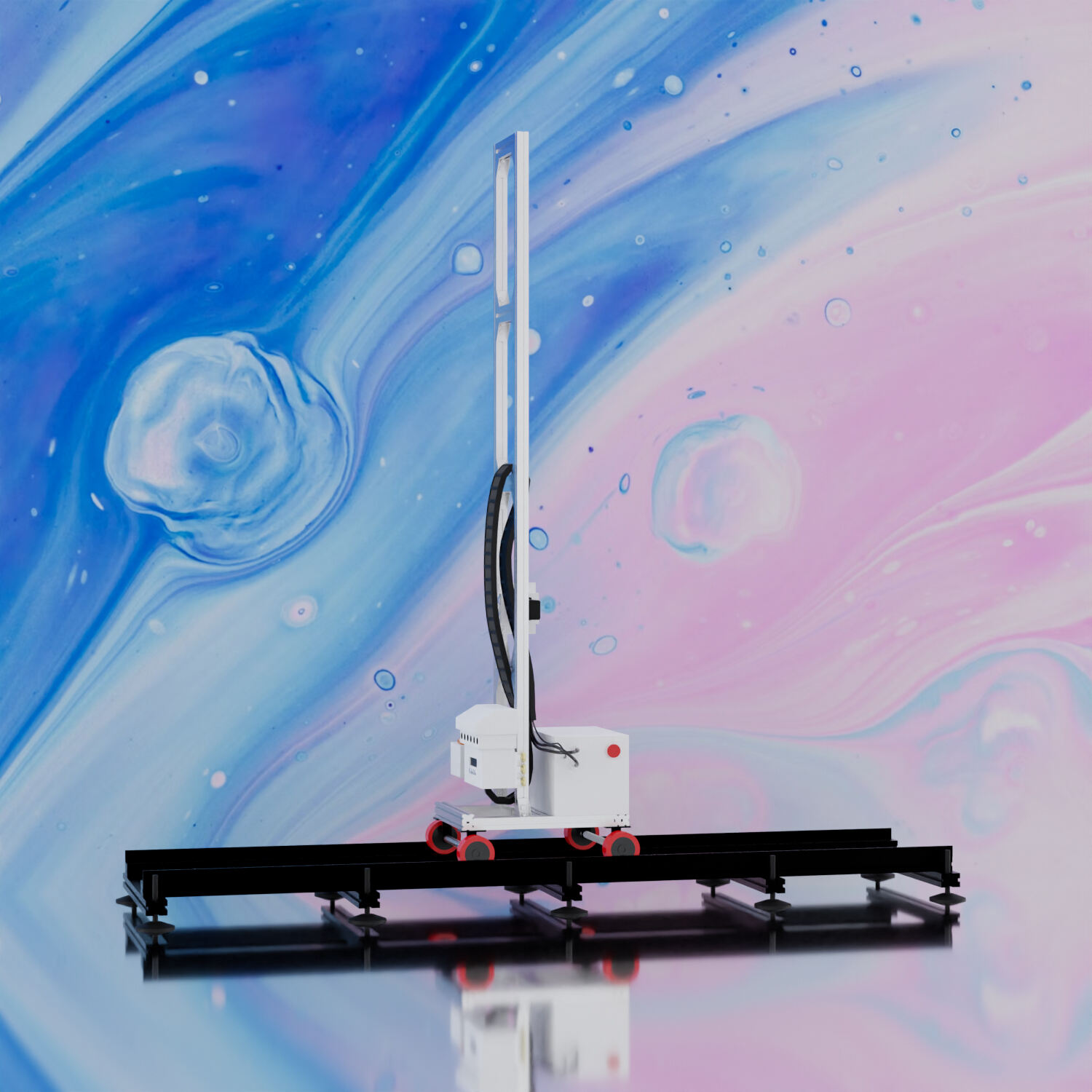

Wall mural printers are a category of automated equipment used to directly print images onto walls or vertical substrates. Their core capability comes from a stable guide rail system and a coordinated motion control system, which together determine p...

VIEW MORE

I. Introduction Laser welding offers advantages such as high energy density, a small heat-affected zone, good weld formation, and low distortion. It is widely used in sheet metal fabrication, consumer electronics, battery manufacturing, medical devic...

VIEW MORE

Laser welding equipment can be divided by operating method and structural form into two main types: desktop laser welding machines and handheld laser welding machines. The two types of equipment show significant technical differences in structural de...

VIEW MORE

QCW (Quasi-Continuous Wave) laser welding machines represent a class of laser welding equipment whose operating characteristics fall between continuous-wave lasers and traditional pulsed lasers. By combining high peak power with relatively long pulse...

VIEW MORE

In laser welding, the laser beam is focused by an optical system onto the surface or interior of the workpiece, forming a region with high energy density. The depth of focus (DOF), as a key parameter describing the spatial energy distribution of the ...

VIEW MORE

In laser processing, whether laser energy can effectively act on a material depends on the material’s ability to absorb a specific laser wavelength. Different materials exhibit significant differences in absorption rates at different wavelength...

VIEW MORE

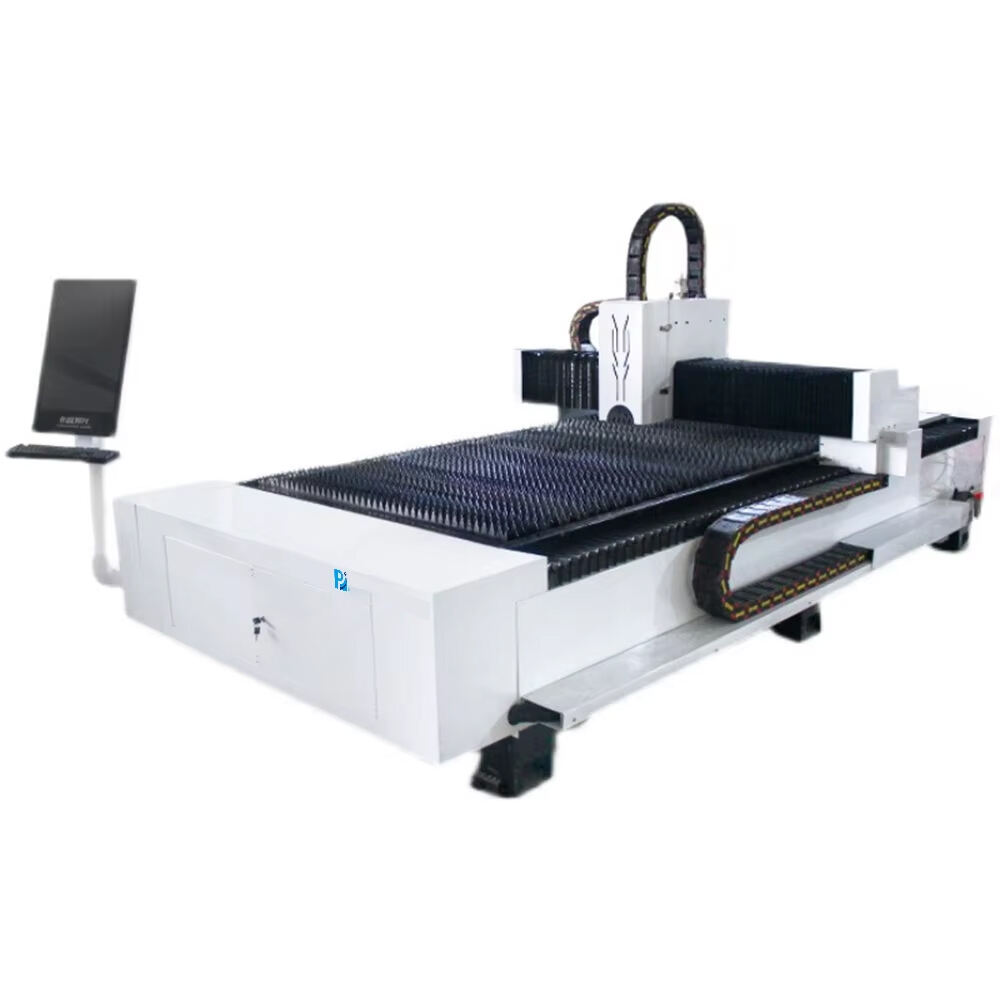

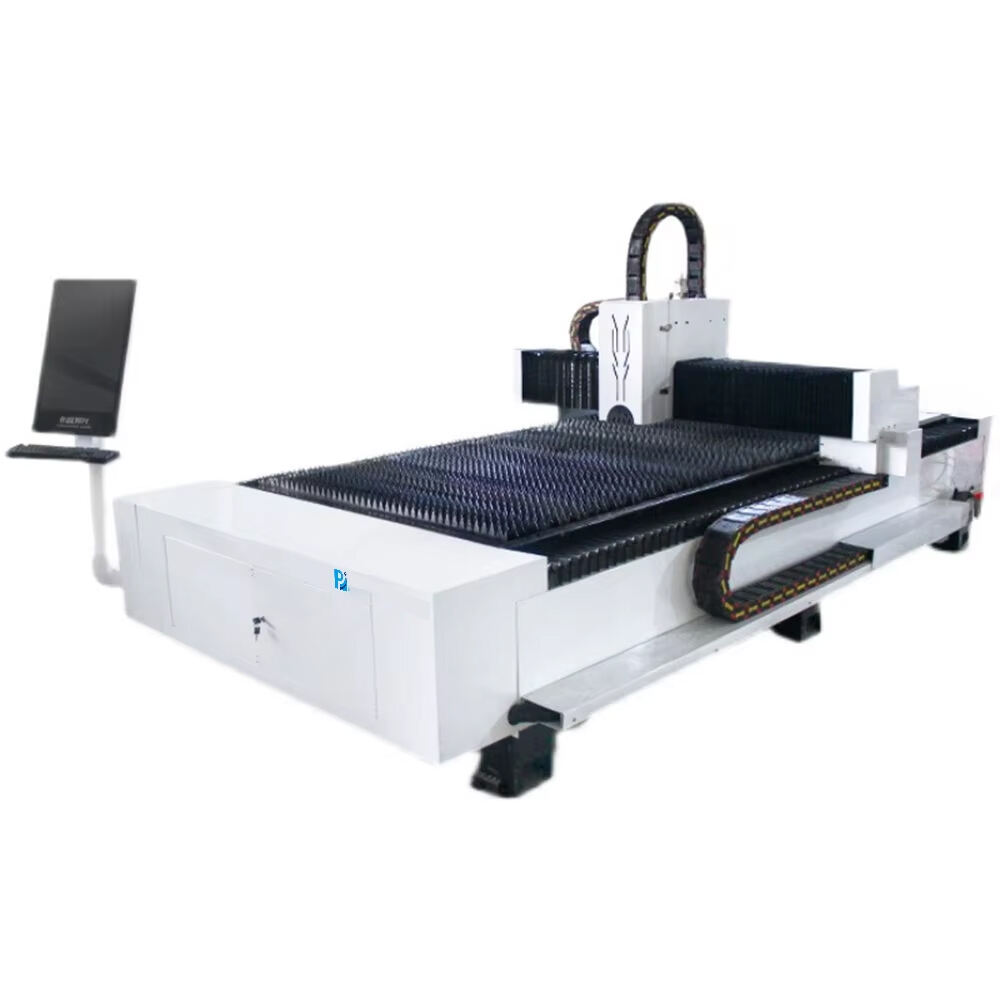

In the field of laser processing, laser cutting systems are mainly divided into galvo scanning systems and linear motion cutting systems. They exhibit significant differences in structural design, motion mechanisms, and applicable scenarios. Understa...

VIEW MORE

In laser cutting processes, focal length and nozzle height are two interrelated key process parameters. They directly affect laser energy distribution, molten pool stability, auxiliary gas performance, and final cutting quality. Proper matching of th...

VIEW MORE

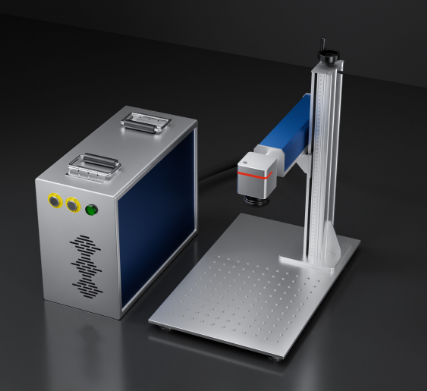

In the field of industrial marking, laser marking, inkjet printing, and screen printing are three commonly used marking technologies. These processes differ significantly in terms of working principles, marking methods, applicable materials, durabili...

VIEW MORE