In the field of industrial marking, laser marking, inkjet printing, and screen printing are three commonly used marking technologies. These processes differ significantly in terms of working principles, marking methods, applicable materials, durability, and operating costs. Selecting an appropriate marking method helps improve product consistency and production efficiency.

1. Differences in Working Principles

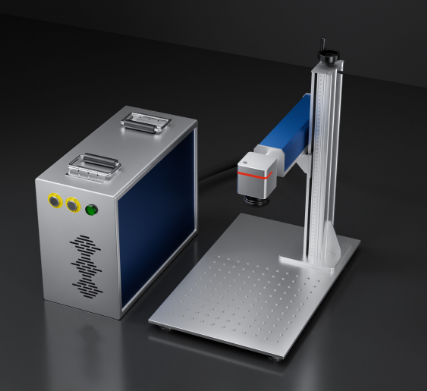

Laser Marking Machine

A laser marking machine uses a high-energy-density laser beam to act on the material surface. Through photothermal or photochemical effects, the material undergoes color change, micro-etching, melting, or vaporization, thereby forming permanent marks. The marking process is non-contact and does not rely on consumables.

Inkjet Printing Process

Inkjet printing forms characters or patterns by ejecting liquid ink onto the product surface through nozzles. The marking quality depends on ink properties, printhead condition, and surface adhesion characteristics.

Screen Printing Process

Screen printing transfers ink onto the workpiece surface through a mesh screen template by mechanical pressure. It is suitable for large-area and repetitive pattern printing. The marking result is strongly influenced by screen accuracy, ink viscosity, and manual operation.

2. Marking Durability Comparison

Laser marking creates structural changes within the material itself. The markings exhibit high resistance to wear, corrosion, and high temperatures, making them suitable for long-term traceability and high-reliability applications.

Inkjet printing and screen printing are surface-adhesion marking methods. Their resistance to abrasion and chemical exposure is relatively limited, and fading or peeling may occur under high temperature, friction, or chemical environments.

3. Applicable Material Range

Laser marking is suitable for a wide range of materials, including metals, stainless steel, aluminum alloys, plastics, ceramics, glass, and rubber. Stable processing can be achieved by selecting appropriate laser wavelengths and power levels for different materials.

Inkjet printing and screen printing require higher surface quality, typically needing flat, clean surfaces with sufficient adhesion. Their adaptability to highly reflective metals, rough surfaces, or high-temperature materials is limited.

4. Processing Accuracy and Consistency

Laser marking is digitally controlled, with characters and graphics generated directly by software. It offers high repeatability and controllable line width, making it suitable for QR codes, micro-text, and high-precision markings.

Inkjet printing is affected by nozzle clogging and ink diffusion, resulting in reduced consistency for fine characters and high-density QR codes.

Screen printing accuracy depends on screen fabrication quality and operational stability, making it suitable for simple patterns rather than high-resolution markings.

5. Production Efficiency and Automation Level

Laser marking machines can be integrated into automated production lines, enabling continuous, high-speed, and unmanned operation. Parameter changes are completed through software settings.

Inkjet equipment is suitable for high-speed conveyor lines but requires frequent printhead maintenance and consumable replenishment.

Screen printing is more suitable for batch production with fixed patterns, has a relatively low automation level, and involves higher costs when changing screens.

6. Operating and Maintenance Costs

Laser marking machines require higher initial investment; however, they do not consume ink or solvents during operation. With long maintenance intervals, the overall operating cost is relatively low.

Inkjet and screen printing equipment have lower initial costs, but long-term operation involves continuous consumption of ink, solvents, and cleaning materials, resulting in higher maintenance and consumable expenses.

7. Application Scenarios

Laser marking is widely used in electronic components, hardware tools, automotive parts, medical devices, and high-end manufacturing industries, particularly for product traceability and anti-counterfeiting identification.

Inkjet printing is commonly used for batch numbers and date coding in packaging, food, and daily consumer goods.

Screen printing is mainly applied to panels, enclosures, nameplates, and applications requiring large-area graphics.

Laser marking machines offer clear advantages in marking durability, precision, consistency, and automation, making them suitable for industrial applications with high requirements for marking quality and stability. Inkjet printing and screen printing remain practical in terms of initial cost and specific application scenarios but have limitations in high-reliability and long-term use.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ