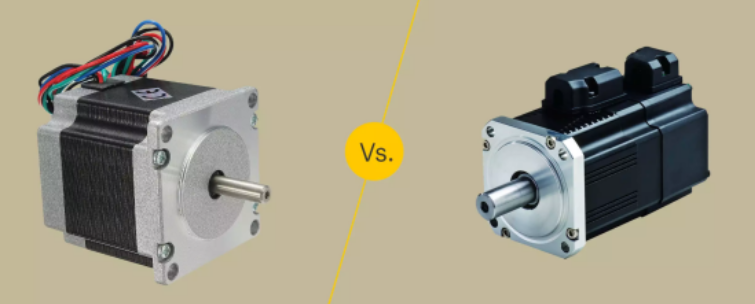

Servo motors and stepper motors are both common electrical actuating components, used for precise control of position, speed and torque. They have fundamental differences in structure, working principle and performance characteristics.

I. Working Principle and Structure

Servo Motor:

Structure: It consists of the motor body (usually a permanent magnet synchronous motor), a high-precision position sensor (such as an encoder), and a drive controller, forming a closed-loop system.

Working principle: The driver receives the pulse sequence and direction signal from the controller, and drives the motor to rotate. The encoder at the rear end of the motor shaft detects the position and speed of the rotor in real time and feeds back the signals to the driver. The driver compares the feedback signal with the command signal, calculates the error, and adjusts the output to eliminate this error.

Stepper motor:

Structure: Composed of the motor body (with multi-phase windings on the stator and a permanent magnet or reactive core rotor) and an open-loop driver.

Working principle: The driver receives pulse signals and sequentially energizes the windings of each phase of the motor, causing the rotor to rotate stepwise by a fixed angle (step angle). Its operation does not rely on position feedback and is an open-loop control.

II. Control Method

Servo Motor: Closed-loop control is employed. The system continuously receives feedback for real-time correction, ensuring that the output is in accordance with the command.

Stepper motor: It adopts open-loop control. After the system issues an instruction, it assumes that the motor has executed accurately without a feedback verification mechanism.

III. Performance Characteristics Comparison

Torque Characteristics:

Servo motor: It has a constant torque output characteristic and can output the rated torque within the rated speed range. It also has overload capability and can typically output 2-3 times the rated torque for a short period of time.

Stepper motor: The output torque drops sharply as the rotational speed increases. It lacks overload capability. Once the load torque exceeds the maximum holding torque of the motor, it will cause disengagement.

Speed range and stability:

Servo motor: Operates smoothly at low speeds, has excellent performance at high speeds, and has a wide speed adjustment range, up to over 1:5000.

Stepper motor: It is prone to vibration at low speeds. At high speeds, the torque drops rapidly and the effective operating speed range is relatively narrow.

Accuracy and Error:

Servo motor: Its accuracy depends on the resolution of the encoder. System error (the difference between the command and the feedback) is transient and will be corrected in real time by the closed-loop system. There is no cumulative error.

Stepper motor: The accuracy depends on the step angle of the motor. There is a cumulative error, meaning the error of each single step will gradually accumulate. During overload, the motor will lose synchronization, resulting in position errors.

Response performance:

Servo motor: Fast response, excellent acceleration performance, suitable for applications requiring rapid start/stop and dynamic load changes.

Stepper motor: Slow response, poor high-speed startup capability, and long acceleration time.

Vibration and Noise:

Servo motor: Runs smoothly with low noise, especially at low speeds.

Stepper motor: It has inherent vibration and noise issues, which are particularly noticeable near the resonance point.

IV. Application Scenarios

Servo Motor: Suitable for applications requiring high precision, high speed, high dynamic response, and torque overload. Examples include industrial robots, CNC machines, high-end automation equipment, and aerospace fields.

Stepper motor: Suitable for cost-sensitive, medium-low speed, stable load, and scenarios with low requirements for smoothness in open-loop control applications. Examples include 3D printers, desktop CNC machines, scanners, and office automation equipment.

V. Cost and Complexity

Servo motor: The system is complex (including the motor, high-resolution encoder, and advanced driver), and the cost is high.

Stepper motor: Simple system, low cost, easy to install and debug.

The choice depends on the overall requirements of the specific application for performance, accuracy, dynamic response and cost.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ