A laser jewelry welding machine is a high-tech device that uses a laser beam as a heat source to precisely connect the metal components of jewelry. Its working principle is based on the interaction between the laser and matter. The core of it is to precisely focus a high-energy-density laser beam onto a tiny area of the workpiece, achieving welding through rapid melting and solidification.

I. Core Working Principle: Interaction between Laser and Metal

Energy Absorption and Conversion:

When a laser beam of a specific wavelength is shone onto the surface of a metal, the free electrons in the metal will absorb the energy of the photons. Jewelry welding machines usually employ pulsed Nd:YAG lasers or fiber lasers, which emit near-infrared light (with a wavelength of approximately 1064nm) that can be effectively absorbed by most jewelry metals such as gold, silver, platinum, and palladium.

Heat accumulation and melting:

The electrons that have absorbed energy collide with the lattice, converting the energy into heat. In an extremely short period of time (usually at the millisecond or microsecond scale), the temperature of the metal at the laser focus rises sharply, rapidly reaching and exceeding its melting point, forming a local molten pool. Due to the high concentration of laser energy, the heat affected zone is very small, and the surrounding materials are basically not damaged by heat.

Melting pool solidification and connection:

After the laser pulse ends, the heat source disappears instantly. The molten metal cools and solidifies by rapidly conducting heat from the surrounding matrix. The metal in the melted zone and the base metal form a common crystal structure during the solidification process, thereby achieving a strong metallurgical connection.

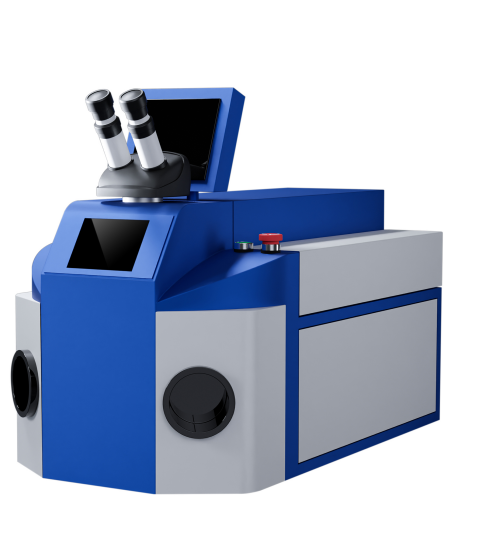

II. Key Components of the System

Laser generator: The core component of the system, responsible for generating laser. Modern devices mostly employ fiber lasers, which have the advantages of high efficiency, good beam quality, and no maintenance requirements.

Light guiding and focusing system: Composed of reflectors, optical fibers and focusing lenses. Its function is to precisely guide and focus the laser generated by the laser generator onto the workpiece, creating a light spot with extremely high energy density.

Workbench and positioning system: Used for fixing and precisely moving workpieces or laser heads. Usually equipped with microscopes, CCD camera systems or cross alignment lights to achieve precise positioning of the welding points.

Control system: An integrated computer and software are used to set and adjust laser parameters such as pulse energy, pulse width, frequency and welding path, controlling the entire welding process.

Protective gas system: In the welding area, inert gas (such as argon) is blown to prevent the high-temperature metal from reacting with oxygen in the air, maintaining the weld point bright and clean.

III. Work Process

Function: Secure the jewelry workpiece to be welded onto the workbench, and precisely align the laser focus with the welding area using the visual system.

Set parameters: Based on the metal material, thickness and welding requirements, set appropriate laser power, pulse duration and frequency in the control system.

Release protective gas: Start the gas line to ensure that the inert gas covers the welding area.

Launch laser: Start the equipment, and the laser emits pulsed laser according to the preset parameters, which acts on the surface of the workpiece.

Forming the solder joint: The laser energy causes the metal to melt instantly, forming a molten pool. After the laser stops, the molten pool solidifies, completing the welding of one solder joint. By moving the workpiece or the laser head, continuous spot welding or seam welding can be carried out.

IV. Technical Features and Application Advantages

Non-contact processing: The laser head does not come into contact with the workpiece, eliminating mechanical stress. It is suitable for delicate and tiny jewelry components.

Small heat-affected zone: The energy is highly concentrated, avoiding the overall heating of the workpiece. This ensures that the already embedded gemstones (especially heat-sensitive gemstones such as tanzanite and opal, as well as enamel materials) will not suffer from thermal damage.

High welding strength: It is a metallurgical bonding method, and the strength of the weld point is close to that of the base material.

Extremely high precision: The spot diameter can reach the micrometer level, enabling nearly invisible welding that requires minimal subsequent polishing work.

Wide range of applicable materials: It can be used for welding various common jewelry metals such as K gold, platinum, silver, and titanium alloy.

The principle of the laser jewelry welding machine is to use a high-energy-density laser beam to locally and instantaneously heat the metal, causing it to melt and achieve metallurgical bonding. The core of its technology lies in the precise control of laser energy, thereby achieving the precise, clean and efficient welding effect required by the jewelry industry.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ