Red-blue light composite welding is a process technology that simultaneously applies infrared laser and blue laser to the welding area. This technology enhances the absorption rate for highly reflective materials through the complementary energy of the two different wavelength lasers, improving the welding stability and forming quality. It is mainly applied in the welding production process of copper and copper alloys.

I. The Functions of Red Light and Blue Light

Infrared light

Infrared light has strong penetrating ability and is suitable for deep fusion welding. For copper materials, when using infrared laser alone, there are problems such as high reflectivity and low energy coupling efficiency, which can easily result in unstable molten pools.

Blue light (450nm band)

The wavelength of blue light is shorter. Copper materials have a high absorption rate in this band, which can quickly form a stable molten pool, improve the initial energy coupling effect, and reduce the risk of reflection.

The core of red-blue light composite welding lies in simultaneously outputting two types of lasers. The blue light is responsible for enhancing material absorption and the stability of the molten pool, while the infrared light provides the main depth of penetration and energy input.

II. The Process Principle of Red and Blue Light Composite Welding

The red-blue light composite welding adopts a multi-path structure, allowing the infrared laser and the blue laser to overlap and focus on the surface of the copper material. The blue light increases the absorption coefficient of the copper surface, facilitating the rapid formation and stability of the molten pool. The infrared light continuously inputs deep energy, making the welding cross-section deeper and more uniform.

The collaborative effect of the two beams can reduce spatter, reduce pores, and improve the welding quality.

III. Advantages in Copper Material Welding

Improve absorption rate

Blue light enhances the absorption of copper materials by laser, concentrating the welding energy and reducing the optical loss caused by laser reflection.

Reduce welding spatter

After the blue light stabilizes the molten pool, the infrared light deep melting process becomes more stable, which can reduce the spatter phenomenon commonly seen in highly reflective materials.

Improve forming quality

The combination of red and blue light can effectively prevent pores, increase the density of the weld seam, and make the weld surface smoother.

Improve welding efficiency

Due to the improvement in energy coupling efficiency, the welding speed can be increased, and the stability of the welding process is higher, making it suitable for mass production.

Suitable for various copper product applications

Including welding requirements for copper sheets, copper foils, copper wires, copper electrodes, copper busbars, and copper terminals of power batteries.

IV. Typical Application Domains

Welding of copper components for new energy batteries

Welding of motor copper wire to copper terminals

Welding of copper material for connectors

Welding of copper heat sinks and copper sheet structural components

Welding of copper precision parts for electronic products

V. Equipment Features

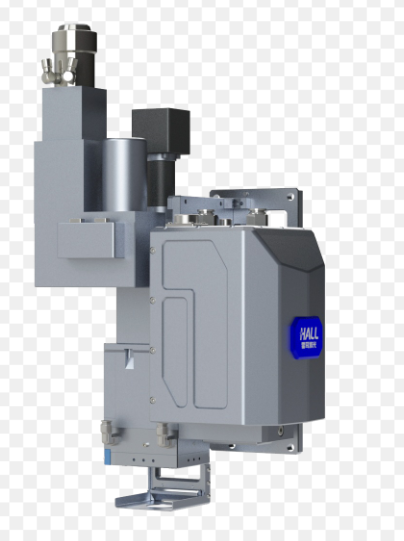

The red-blue light composite welding equipment usually adopts a dual-light source or multi-light source coupling structure, featuring independent power control, real-time monitoring of the molten pool status, and high stability output characteristics. The equipment supports multiple welding modes, such as continuous welding, mirror oscillation welding, and swinging welding, and can meet the requirements of different copper material thickness and structural designs.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ