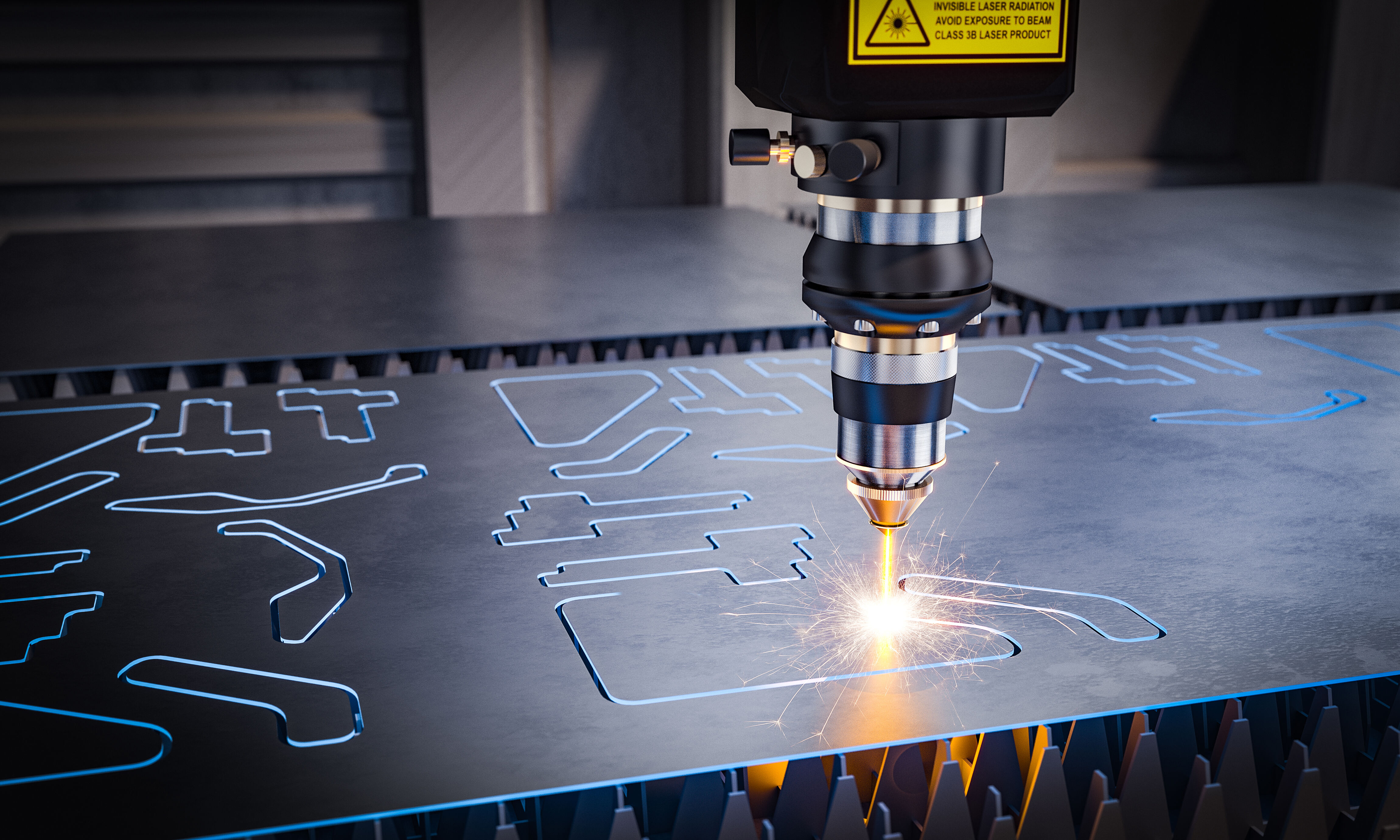

Optical lenses play a core optical role in laser processing equipment, measuring instruments, imaging systems, and optical communication devices. The surface cleanliness of these lenses directly affects the transmittance, imaging quality, and stability of the system. To ensure the long-term reliable operation of optical components, it is necessary to adopt standardized cleaning procedures and appropriate materials, and avoid surface damage and residual contamination.

I. Types of Pollution and Their Effects

Common contaminants of optical lenses include:

Particle pollution: Dust, metal shavings, fibers, etc. These are solid micro-particles. They can cause scattering of light, reduce transmittance, and in severe cases, cause scratches on the coating.

Oil contamination: Organic substances such as fingerprints, sebum, and lubricating oil. This can cause local absorption and heating, reduce the quality of the light beam, and affect the stability of the laser equipment.

Chemical pollution: Residues from cleaning agents, deposition of volatile substances in the environment. This can corrode the coating layer or cause changes in transmittance.

Vapor contamination: Condensation droplets and moisture adsorption. This will affect the coating performance and cause optical path deviation.

Different types of pollution require the use of different cleaning methods and materials to avoid secondary damage.

II. Cleaning Materials and Tools

The cleaning of optical lenses must use materials that meet optical standards, including:

Dust-free wiping paper or optical lens paper: High fiber purity, no debris shedding.

Anti-static gloves: Prevent sebum from adhering.

Dust blowing canister or ionized air: Used for removing non-adherent particles.

Optical grade cleaning solution: Commonly used is anhydrous ethanol, anhydrous isopropanol or a specific formulation cleaner.

Pliers and lens holder: Used to prevent direct contact of the hand with the edge of the lens.

The materials must be kept in a clean state to avoid cross-contamination.

III. Standard Cleaning Procedure

1. Initial Dust Removal

Use an oil-free compressed air or dust blowing tank to blow the lens surface at an appropriate angle to remove loose particles and prevent scratches caused by subsequent cleaning.

2. Targeted Cleaning

For local oil stains or fingerprints, you can use lens paper and apply a small amount of cleaner. Gently press and wipe in one direction to avoid spreading the contamination through repeated back-and-forth movements.

3. Comprehensive Cleaning

If necessary, fix the lens onto the bracket. Dip a folded optical cleaning paper in the cleaning solution and move it in a single-directional arc from the center outward. Replace the paper each time and ensure that a new contact surface is used for each wipe.

4. Drying treatment

After cleaning, it should be allowed to dry naturally or dried with low-pressure clean gas to avoid any water marks remaining.

IV. Operating Precautions

Avoid using industrial-grade tissues or ordinary fabrics to prevent scratches and fiber residue.

The cleaner must be completely evaporated and no visible stains should remain.

The cleaning action should be gentle. Excessive pressure will damage the coating layer.

The environment should be maintained at a clean level to reduce the deposition of particulate matter in the air.

A regular inspection system should be established for the optical components of high-power laser systems to assess the rate of coating damage and contamination.

V. Cleaning Frequency and Maintenance Strategies

The frequency of cleaning optical lenses is determined based on the application environment, power density and usage duration. The recommended strategy is as follows:

Laser processing of lenses: Clean as needed based on the degree of contamination. It is not recommended to over-clean to avoid cumulative damage.

Precision inspection lens: Regularly check, clean immediately upon contamination.

Closed optical path system: Conduct quarterly maintenance, with a focus on checking the sealing performance and the condition of the desiccant.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ