I. The Principle of Double Red Light

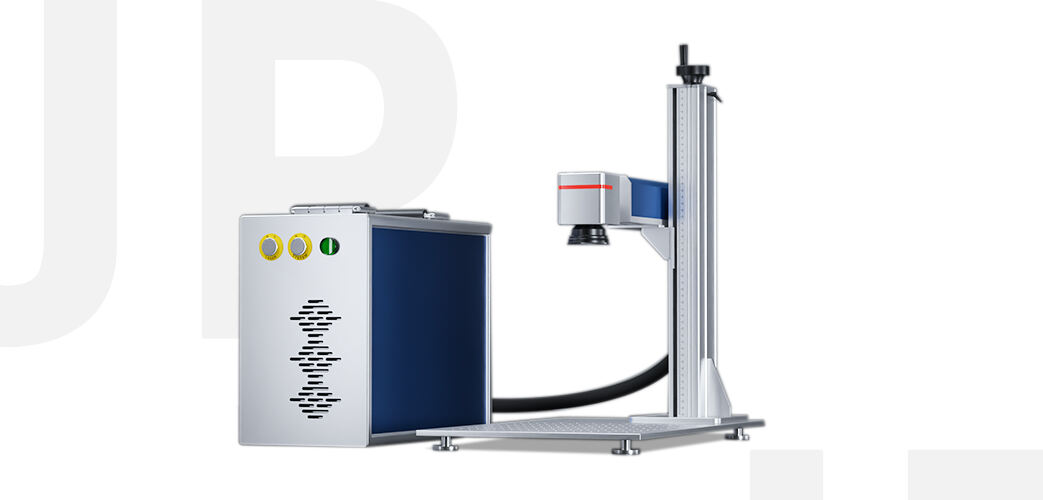

The dual red light system of the laser marking machine consists of two sets of indicator lights, and usually adopts a coaxial or quasi-coaxial optical path design. The dual red lights are superimposed with the main laser light path through an optical beam combiner, ensuring that the indicator lights are in the same position as the laser focus. The system uses the intersection points formed by the two red lights on the workpiece surface to achieve feedback on the focal position through the minimization state of the intersection points.

When the processing head moves or adjusts the height of the Z-axis, the distance between the two red light intersections changes. The operator determines whether the focus position is on the optimal focal plane based on the spacing of the intersections. When the intersections coincide or reach the preset spacing, it indicates that the focal length has met the process requirements. This method relies on the coaxiality of the optical path, the performance of the indicator light collimation, and the calibration parameters of the focal length, and is suitable for rapid focusing and precise positioning operations.

II. Advantages of Dual Red Light Application

1. High efficiency in focal point positioning

The dual red light can achieve real-time focal point assistance positioning, without relying on material ablation and etching verification. It is suitable for processing tasks that require frequent changes in height, such as the switching of different thickness workpieces and multi-plane processing.

2. Stable positioning accuracy

Due to the optical coaxiality between the dual red light and the main light beam, the focal length error can be kept within a controllable range. Compared to the single red light, the focus determination of the dual red light is more intuitive, reducing the focal length error caused by beam deviation.

3. Compatible with various beam types

The dual red light system is compatible with the optical paths of picosecond, nanosecond, MOPA fiber lasers and ultraviolet lasers. By adjusting the indicator light collimating mirror group, it can adapt to the depth range of different focal length Fθ lenses.

4. Highly adaptable to curved workpieces

On curved or stepped workpieces, the dual red light can provide multiple point position determination, enabling operators to quickly identify the areas where the focus changes. It can be used for process debugging of curved marking, recess area marking, and multi-plane marking.

5. Reducing marking defects caused by focal length errors

Precise focal length can reduce the variation in energy density, avoiding processing problems such as excessive burning, unclear marking, and abnormal line width due to focal length deviations, and improving the consistency of marking.

6. Suitable as an automated visual auxiliary signal

The dual red light can serve as a visual positioning aid, being used in automated equipment for identifying the position of workpieces, indicating the boundary of the marking area, and providing algorithmic assistance for the Z-axis automatic focusing module.

III. Application Scenarios

The dual red light system is applicable to the following application areas of laser marking machines:

2. Metal surface engraving and QR code marking

3. Shallow processing of materials such as plastics and ceramics

4. Batch marking of multi-height structures

5. Positioning Assistance for Automated Clamping Fixtures

6. Focal length calibration of small precision components

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ