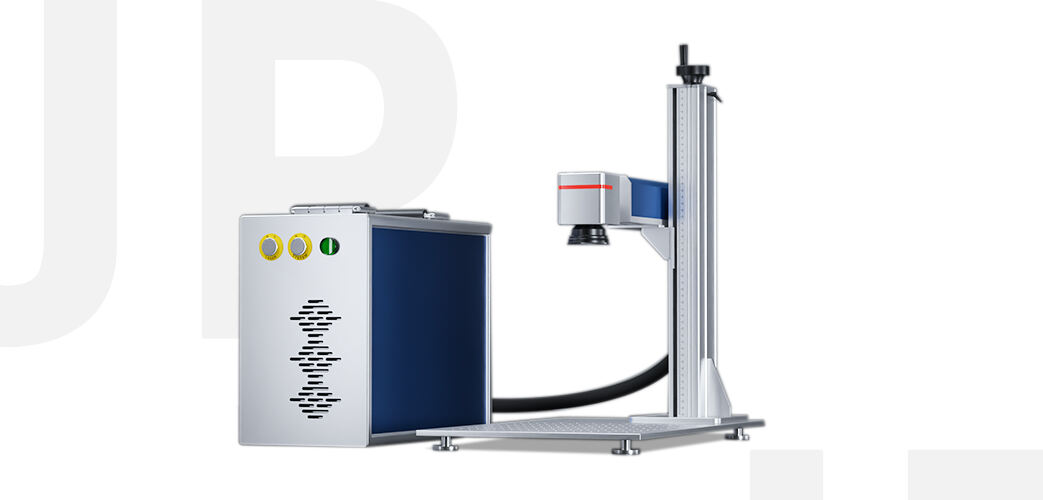

Durante l'incisione laser, lo specchio di campo svolge un ruolo cruciale. Comprendiamone e analizziamone la funzione.

1. Cos'è uno specchio di campo?

Lo specchio di campo è un componente fondamentale del sistema ottico di una macchina per marcatura laser. Viene solitamente installato dopo il sistema di scansione a specchi. Il suo compito principale è focalizzare il fascio laser deviato e riflesso dallo specchio in un punto luminoso altamente concentrato e estremamente piccolo, garantendo che questo punto formi un'area di scansione piatta e priva di distorsioni sulla superficie da marcare.

II. Le Tre Funzioni Principali delle Lenti di Campo

Le funzioni delle lenti di campo vanno ben oltre la "messa a fuoco". Si manifestano specificamente nei seguenti tre aspetti chiave:

Funzione Principale: Concentrare l'Energia Laser

Questa è la funzione più fondamentale della lente di campo. Dopo che il raggio laser ha attraversato l'espansore del fascio ed è stato collimato, anche se si tratta di un fascio parallelo, la densità energetica è relativamente dispersa e non può essere utilizzata direttamente per la lavorazione. La lente di campo, grazie al suo preciso design della superficie curva, concentra il fascio laser parallelo incidente in un punto molto piccolo. Secondo i principi ottici, la densità energetica nel punto focale aumenta esponenzialmente, raggiungendo la soglia necessaria per la vaporizzazione istantanea o per modificare le proprietà fisiche e chimiche della superficie del materiale, realizzando così lo scopo della marcatura e dell'incisione. Più corta è la lunghezza focale della lente di campo, maggiore è la capacità di focalizzazione, minore è il diametro del punto luminoso e più elevata è la densità energetica, rendendola più adatta a lavorazioni di precisione.

2. Funzione Principale: Realizzare la Scansione a Campo Piatto

Questo è ciò che distingue la lente di campo dalle comuni lenti convesse. Se si utilizzano solo lenti ordinarie, quando il motore dello specchio di scansione devia, la posizione del fuoco del raggio laser sul piano di marcatura cambia, generando una forma sferica del piano focale (cioè "curvatura di campo"). Ciò significa che i bordi del piano di marcatura si troveranno davanti o dietro al fuoco, risultando sfocati e insufficienti in termini di energia.

La lente di campo, grazie a un design ottico speciale, può "appiattire" il campo focale sferico creato dalla scansione dello specchio in un piano. Indipendentemente dall'angolo con cui il raggio laser incide sulla lente di campo, questa riesce a focalizzarlo sullo stesso piano. Ciò garantisce che, all'interno dell'intero campo di marcatura (ad esempio 100 mm x 100 mm), le dimensioni e la densità energetica del punto luminoso rimangano costanti in ogni punto, consentendo così un effetto di marcatura di alta qualità con bordi nitidi e profondità uniforme sia al centro che in periferia.

3. Ruolo decisionale: Definire la gamma di marcatura e le dimensioni del punto

La lunghezza focale dell'obiettivo influisce direttamente su due parametri prestazionali chiave della macchina per marcatura laser:

Gamma di marcatura: Maggiore è la lunghezza focale dell'obiettivo, più ampia sarà la gamma di marcatura. Ad esempio, un obiettivo con lunghezza focale di 100 mm potrebbe avere una gamma massima di marcatura di 100 mm x 100 mm, mentre un obiettivo con lunghezza focale di 330 mm potrebbe raggiungere i 300 mm x 300 mm. Tuttavia, a fronte di ciò, durante la marcatura su aree ampie, la densità energetica sarà relativamente inferiore.

Dimensioni del punto: Minore è la lunghezza focale dell'obiettivo, più piccolo sarà il punto focalizzato e maggiore sarà la precisione di lavorazione. È adatto alla marcatura ultrafine come micro fori, codici QR e motivi dettagliati. Tuttavia, corrispondentemente, anche la sua area di marcatura sarà più ridotta.

Pertanto, gli utenti devono selezionare la lunghezza focale dell'obiettivo campo in base alle dimensioni e ai requisiti di precisione del pezzo in lavorazione, effettuando un compromesso tra l'area di marcatura e la precisione di lavorazione.

III. Parametri tecnici principali e linee guida per la selezione degli obiettivi campo

La selezione dell'obiettivo campo appropriato è fondamentale per ottimizzare l'effetto di marcatura:

Lunghezza focale: come menzionato in precedenza, è il criterio primario di selezione.

Breve lunghezza focale (ad esempio F=100mm - 163mm): area ridotta, alta precisione, elevata densità energetica. Adatto per marcature fini su componenti elettronici, dispositivi medici, gioielli, wafer di silicio, ecc.

Lunghezza focale media (ad esempio F=210mm - 254mm): offre il miglior equilibrio tra area e precisione ed ha la massima versatilità. Adatto per la marcatura di loghi e numeri di serie sulla maggior parte dei prodotti in metallo e plastica.

Lunghezza focale lunga (ad es. F=330mm - 420mm): adatta per la marcatura su ampia scala o per la marcatura su superfici curve 3D (grazie alla maggiore profondità di campo). Applicabile a parti automobilistiche, lamiere grandi, ecc.

Dimensione del spot luminoso in ingresso: l'obiettivo campo ha un limite massimo di apertura. È necessario garantire che il diametro del fascio laser in uscita dal galvanometro sia inferiore al diametro consentito del spot luminoso in ingresso dell'obiettivo campo. In caso contrario, la luce ai bordi verrà bloccata, causando perdita di energia e deformazione del spot.

Profondità di campo: indica l'intervallo di profondità entro il quale si possono ottenere immagini nitide prima e dopo il punto focale. La profondità di campo di un obiettivo campo con lunghezza focale lunga è maggiore e richiede minori requisiti di planarità della superficie del pezzo. È più adatto per la marcatura su superfici curve leggermente ondulate.

Rivestimento: Rivestimenti antiriflesso di alta qualità possono ridurre significativamente le perdite per riflessione del laser sulla superficie della lente, migliorare l'utilizzo dell'energia e proteggere la lente dai danni causati dall'alta temperatura. Il rivestimento deve essere selezionato in base alla lunghezza d'onda del laser (ad esempio 1064 nm, 10,6 μm, 355 nm).

IV. Manutenzione e cura delle lenti di campo

Essendo componenti ottici di precisione, le lenti di campo richiedono una manutenzione accurata:

Antipolluzione: Il fumo e le sostanze spruzzate generate durante il processo contaminano la superficie della lente di campo, ne alterano la trasmissione luminosa e l'effetto di marcatura, e possono addirittura provocare crepe nella lente a causa di un assorbimento termico localizzato.

Metodo di pulizia: Utilizzare soffietto professionale, alcol anidro e carta per la pulizia delle lenti. Pulire delicatamente la lente con movimento a spirale, partendo dal centro verso il bordo.

Protezione dagli urti: Evitare qualsiasi contatto fisico per prevenire danni alla superficie ottica.

In conclusione, anche se l'obiettivo di campo è di dimensioni ridotte, rappresenta uno dei componenti fondamentali del sistema ottico di una macchina per marcatura laser. Esso non solo agisce come concentratore di energia, ma funge anche da "dispositivo livellatore" del piano di scansione, determinando direttamente l'accuratezza, l'ampiezza e l'uniformità dell'operazione di marcatura. Nella selezione e configurazione di un sistema di marcatura laser, è essenziale comprendere appieno i principi e le funzioni dell'obiettivo di campo, scegliere quello più adatto in base alle effettive esigenze applicative ed eseguire regolarmente la manutenzione. Questo passaggio è indispensabile per garantire che l'apparecchiatura operi nelle condizioni ottimali e raggiunga risultati di lavorazione perfetti.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ