When manufacturing precision entered the micrometer era, Jiangpin Technology reshaped the industrial boundary with solid-state lasers - this "blade of light" with solid-state crystals as its energy core, featuring precise welding and marking accuracy, and wavelengths spanning from infrared to ultraviolet, has inscribed the yardstick of Chinese precision in the veins of PCB boards, battery cores, and screens. Now let's take a look at solid-state lasers together:

Solid-state lasers are lasers based on solid-state gain media (such as crystals or glasses doped with rare earth or transition metal ions), which can generate output power ranging from several milliwatts to several kilowatts. Many solid-state lasers use flash lamps or arc lamps for light pumping. These pumping sources are relatively inexpensive and can provide very high power, but their efficiency is rather low, their lifespan is average, and there are strong thermal effects in the gain medium, such as the thermal lensing effect. Laser diodes are most commonly used to pump solid-state lasers, and these laser-pumped solid-state lasers (DPSS lasers, also known as all-solid-state lasers) have many advantages, such as compact installation, long lifespan, and excellent beam quality. Its working mode can be continuous wave, that is, it can generate continuous laser output, or pulse type, that is, it can produce short-time high-power laser pulses.

Working principle:

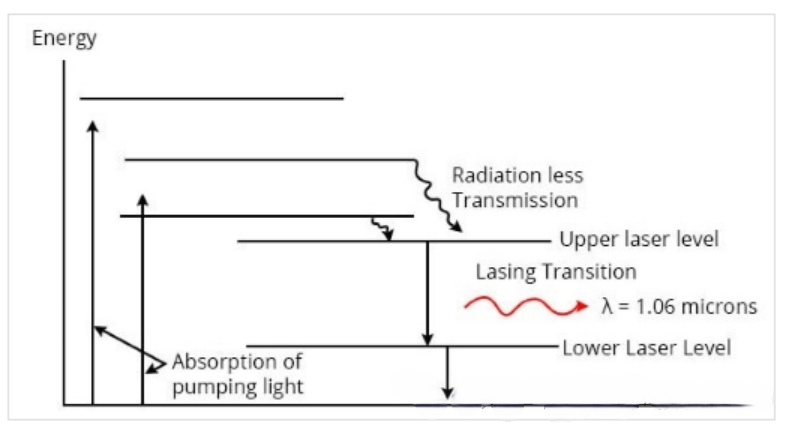

The activation medium used in solid-state lasers is solid material. Usually, all solid materials adopt optical pumping, that is, the light source is used as the energy source to apply energy to the gain medium. The electrons in the gain medium are excited to a higher energy level after absorbing the pump energy. In the excited state, some electrons will transition from higher energy levels to specific metastable energy levels. The lifetime of metastable states is longer than that of other excited states, so energy can be used for storage and accumulation. When an electron in a metastable state transitions back to the ground state, it emits a photon with a specific energy and wavelength. The generated photons undergo multiple reflections within the laser cavity. This feedback mechanism amplifies the stimulated radiation, thereby generating a strong laser beam. Some of the amplified light passes through some of the mirrors, forming a laser output. The output beam usually has a narrow linewidth and is characterized by a specific wavelength related to the energy difference between the metastable state and the ground state.

Solid-state laser type:

The output power of small diode-pumped Nd:YAG lasers (YAG lasers) or Nd:YVO4 lasers (vanadate lasers) is typically between several milliwatts (for micro-devices) and several watts. The pulse duration generated by the Q-switched laser is several nanoseconds, the pulse energy is microjoules, and the peak power is as high as several kilowatts. Intra-cavity frequency doubling can be used for green light output.

Q-switched Nd:YAG lasers are widely used in lamp-pumped versions. Pulse pumping allows for high pulse energy, while the average output power is usually moderate (for example, a few watts). The cost of this type of lamp-pumped laser is lower than that of the diode-pumped version with a similar output power.

Fiber lasers are a special type of solid-state laser, featuring potential for high average output power, high power efficiency, high beam quality and wide wavelength tunability.

Solid-state lasers (especially represented by fiber lasers and diod-pumped solid-state lasers) have taken a dominant position in a wide range of fields such as metal processing, precision micro-processing, and hard tissue medical treatment, thanks to their excellent short-wavelength characteristics, extremely high beam quality, powerful ultra-short pulse capability, compact structure, extremely high reliability and low maintenance requirements. And it continuously promotes the innovation and development of laser technology. The ultimate choice of technology depends on a comprehensive consideration of specific application requirements, material properties and cost-effectiveness.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ