In the field of handicraft making, laser engraving machines, with their features of high precision, high efficiency and non-contact processing, are gradually becoming an indispensable innovative tool. It can not only precisely transform the designer's creativity into physical objects, but also bring brand-new artistic effects and technological possibilities to the production of traditional handicrafts. This article will delve deeply into the application of laser engraving machines in the production of handicrafts and demonstrate how they are injecting new vitality into this field.

I. Basic Principles of Laser Engraving Machines

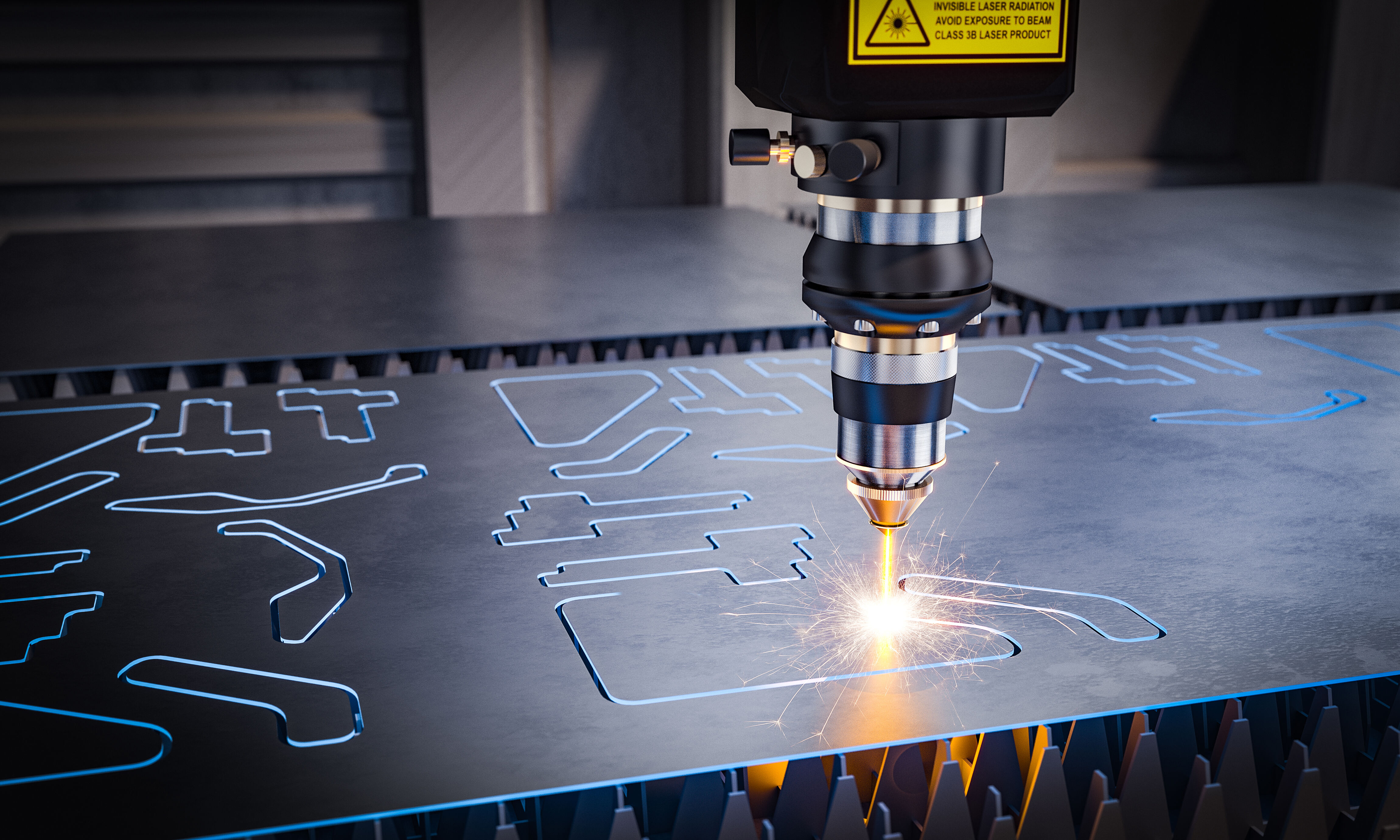

Laser engraving machines use high-energy laser beams as processing methods. Under computer control, they precisely engrave design patterns on the surface or interior of materials. The focusing and directionality of the laser beam enable the engraving process to achieve extremely high precision and detailed representation. Meanwhile, laser engraving is a non-contact processing method, which avoids the material damage and deformation that traditional engraving tools may cause, ensuring the quality and integrity of the engraved works.

Ii. Application of Laser Engraving Machines in Handicraft Making

Wooden handicrafts

Wooden handicrafts are one of the most widely used fields for laser engraving machines. Laser engraving machines can engrave fine and exquisite patterns and characters on the surface of wood, such as human portraits, landscape paintings, animal images, etc. Its high-precision engraving ability makes the works rich in details, distinct in layers and of high artistic value. In addition, laser engraving can also achieve a bas-relief effect on wood, enhancing the three-dimensional effect and layering of the work.

2. Metal handicrafts

In the production of metal handicrafts, laser engraving machines also perform exceptionally well. It can engrave fine patterns and textures on the metal surface, such as geometric shapes, animal patterns, floral patterns, etc. Metal works engraved by laser not only possess a unique artistic style, but also can be further enhanced in terms of visual effect and decorative value through processes such as oxidation and coloring.

3. Glass and crystal handicrafts

Laser engraving machines also have extensive applications in the production of glass and crystal handicrafts. Through laser engraving, exquisite patterns, characters and relief effects can be formed on the surface of glass or crystal. Under the illumination of light, these works can display charming luster and unique artistic charm.

4. Leather and Textiles

Leather and textiles are also common application materials for laser engraving machines. Laser engraving machines can engrave delicate patterns and designs on the surface of leather, adding a unique artistic touch to leather products. On textiles, laser engraving machines can achieve fine hollowing and cutting effects, creating textile artworks with a three-dimensional and layered effect.

Iii. Advantages of Laser Engraving Machines

1. High precision and detailed presentation

Laser engraving machines can achieve extremely high engraving precision and detailed representation, making the works rich in details and distinct in layers, and possessing high artistic value.

2. Non-contact processing

Laser engraving is a non-contact processing method, which avoids the material damage and deformation that traditional engraving tools may cause, ensuring the quality and integrity of the engraved works.

3. Wide adaptability of materials

Laser engraving machines are suitable for engraving processing of various materials, including wood, metal, glass, crystal, leather and textiles, etc., providing a rich selection for the production of handicrafts.

4. Integration of design and processing

The combination of laser engraving machines and computer design software enables designers to directly transform design patterns into engraving works, achieving the integration of design and processing, and significantly enhancing work efficiency and creative freedom.

The application of laser engraving machines in the production of handicrafts not only brings brand-new artistic effects and technological possibilities to traditional handicraft making, but also provides rich creative means and sources of inspiration for modern handicraft design. With the continuous development and improvement of laser technology, the application prospects of laser engraving machines in the field of handicraft making will be even broader. In the future, we can look forward to the emergence of more laser-engraved handicrafts with unique artistic styles and creativity, adding more artistic enjoyment and aesthetic experience to people's lives.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ