Pozitionare vizuală a marcarei cu laser

În domeniul fabricației cu precizie de grad industrial, tehnologia de marchetare cu laser vizual a devenit una dintre tehnologiile de bază pentru a realiza reperarea produselor, controlul procesului și gestionarea calității. Ca un reprezentant inovator în acest domeniu, echipamentele Jiangpin Technology integrează cele trei metode principale de poziționare vizuală: pe axa laterală, coaxială externă și coaxială internă. Prin colaborarea camerelelor CCD de precizie și galvanometrele laser, aceasta îmbunătățește semnificativ precizia și eficiența marchetării. Următoare este o analiză profundă din trei perspective: principii tehnice, comparări de performanță și aplicații industriale.

I. Principii tehnice și caracteristici ale celor trei metode majore de poziționare vizuală

Sistem de viziune off-axă

Sistemul de control al marcarei cu laser cu vizion laterală pe axă este montat lângă sistemul optic, care este sistemul de control al marcarei cu laser cu vizion laterală pe axă. Camera sa este montată la un unghi fix pe latura galvanometrului laser, iar poziționarea se realizează prin algoritmi de lipire a imaginilor și transformare a coordonatelor. Avantajele stau în structura sa simplă și costul scăzut, ceea ce o face potrivită pentru marcare în formate mari. Cu toate acestea, depinde de o calibrare precisă și este predispusă erorilor de parallaxă (de obicei ±0,1mm) pe suprafețe curbe sau piese cu diferénțe mari de înălțime. Este folosit majoritar în scenarii de marcare a ambalajelor și fețelor plane, unde cerințele de precizie nu sunt stricte.

Sistem Extern Coaxial de Viziune

Coaxialitatea externă se referă la coaxialitatea sistemului de vizionare și a laserului în afara sistemului optic. Camera este cuplata cu calea laser prin intermediul unui splitter de rază pentru a realiza coincidența focarului laser cu centrul câmpului de vedere al imaginii. Tehnologia Jiangpin adoptă această metodă în mașinile de marchetaj PCB, combinată cu tehnologia de poziționare a punctului Mark, cu o precizie de ±0,05 mm. Avantajul său constă în eliminarea paralaxe, făcând-o foarte potrivită pentru grabări de coduri QR pe plăci multiple sau circuite flexibile (FPCS), și susține prelucrarea rapidă a 60-80 de coduri pe minut. Cu toate acestea, structura calei optice este complexă și costul de întreținere este relativ ridicat.

Sistem de Viziune Coaxial Integrat

Coaxial intern se referă la montarea sistemului de vizionare în interiorul sistemului de control al galvanometrului, realizând trase optice coaxiale. Camera miniaturizată este integrată direct în cavitatea optică a galvanometrului, iar traseul optic de imaginare este complet coaxial cu traseul optic al laserului. Aceasta este în prezent cea mai precisă soluție (până la nivelul μm), fiind special indicată pentru marchetarea dispozitivelor micro - precum plăci micro și stenturi medicale. Tehnologia Jiangpin a implementat această tehnologie în modelele sale de top, rezolvând problema focalizării suprafețelor curbe prin focalizare Z-axă în timp real, reducând timpul de poziționare cu peste 25%.

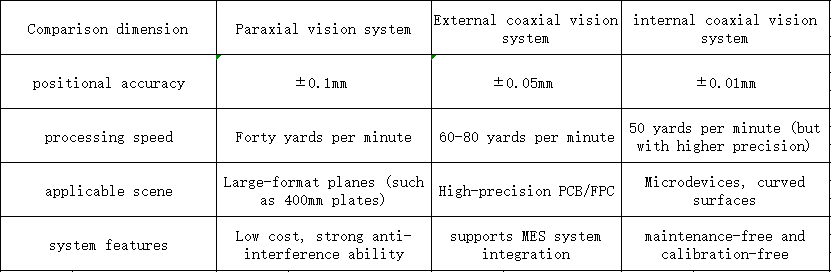

Ii. Compararea performanței: date măsurate privind acuratețe, viteză și eficiență

Performanța celor trei sisteme în scenariile industriale poate fi comparată clar prin următoarea tabelă:

Sistemul coaxial extern reduce intervenția manuală prin legarea poziționării automate CCD și citirea codurilor după imprimare, scurtând timpul de comutare al liniei de producție cu 70%.

Sistemul coaxial utilizează galvanometru de mare viteză (viteză de scaneare > 3000mm/s) și algoritmi de umplere adaptativi (cum ar fi umplerea cu arc), creșterea vitezei cu 40% în marcarea graficelor fine.

III. Situații de adaptație profundă la scenarii de aplicare industriale

Trasabilitate integrală a PCB

În fabricarea electronică, mașina de marcare coaxială exterioară a tehnologiei Jiangpin poate să grave coduri QR microscopice de 1.5×1.5mm pe suprafața PCB-urilor cu ulei verde/negru și să se conecteze la mașinile de montare superioare și inferioare prin intermediul interfeței SMEMA pentru a realiza operațiuni fully automate ale liniei de montaj. Echipamentul citește automat codul QR și îl returnează sistemului MES. Produsele defecte vor fi semnalate imediat, înlocuind costurile consumabile ale codificării tradiționale cu jet de ink.

Marcarea dispozitivelor medicale de precizie

Sistemul coaxial este folosit pentru marcare pe suprafețe curbe polionate, cum ar fi șurubele de os și articulațiile artificiale. Formează marche permanente prin intermediul unui mecanism termocromic (fără ablație), evitând deformarea cauzată de stresul materialului 46. Comparativ cu fresa mecanică, rata de producție a crescut până la 99,9%.

Linia de producție flexibilă poate să se comute rapid

Sistemul cu axă laterală demonstrează flexibilitate în linia de producție a pieselor auto. Prin schimbarea fixturilor și a soluțiilor presetate în software, poate să comute între diferite lucrări pentru marcare în interiorul unui interval de 10 minute, susținând producția mixtă a mai multor materiale, cum ar fi semnele metalice și piesele din cauciuc.

IV. Direcția Evoluției Tehnologice: Inteligența și Integrarea

Tehnologia viitoare de marcare laser cu vizualizare va face progrese în trei dimensiuni:

Compensare vizuală AI: Previziunea deformării termice a materialelor prin învățare adâncă și ajustarea dinamică a traiectoriei de marcare (cum ar fi compensarea dilatarii materialelor din cupru datorită căldurii ridicate);

Fuziune multispectrală: Lazele ultraviolete/verde/de fibra lucrează în coordonare cu sistemele de vizionare pentru a se adapta la toate scenariile, de la plăci de siliciu la materiale compuse;

Design modular: Noul generat de echipamente al tehnologiei Jiangpin suportă inserarea și eliminarea rapidă a lentilelor axiale laterale și coaxiale externe, îndeplinind cerințe de multi-precință cu o singură mașină.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

AZ

AZ

KA

KA

LA

LA

UZ

UZ