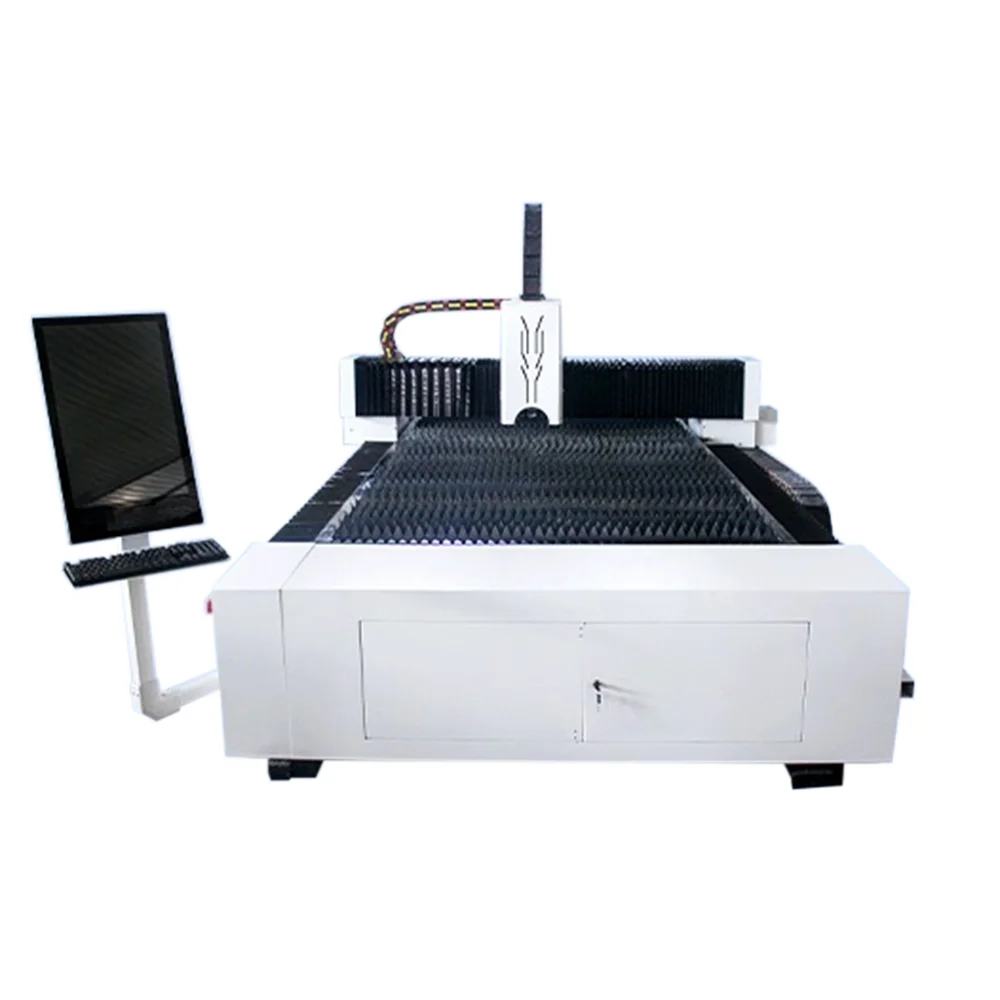

Today in this fast-developing manufacturing industry, steel plate laser cutting machine is gaining more and popularity. The efficiency and accuracy these machines provide in making numerous steel products make them irreplaceable. This is contrary to more traditional means of cutting which usually can only cut alloys and non-metals, with metal's properties the most widely varied. This flexibility has enabled companies to explore new possibilities in design and production of high-quality goods.

One of the biggest benefits offered by steel plate laser cutting machine being their high level or precision. No other shop tools can cut through such rugged materials so easily and leave long, clean cuts without the slightest hint of twisting or warping. As a result, they can deliver high level accuracy when creating complex shapes and designs to achieve exclusive pieces which could lay them apart from their competitors.

The more significant reduction in production times compared to traditional cutting techniques is a different indispensable benefit brought forth through steel plate laser cutting machines. These high-end machines allow a single operator to smoothly change between multiple designs, thus delivering higher production outputs and streamlining the manufacturing process. Further to this, these machines are compatible with different software applications enabling manufactures in minimizing the wastage and also deploying raw materials most efficiently.

With the arrival of steel plate laser cutting machines, a new wave of manufacturing revolution has been ushered in owing to their speed precision and flexibility. Manufacturers can use it to produce a greater variety of products with heightened accuracy even some that require very intricate designs. Speed, precision and large-scale customization in such cutting-edge machines allow for high-quality yet quick production at an economical price factor.

Moreover, with the cutting precision of higher standards, steel plate laser cutting machinery have alsomost importantly made possible to manufacture products that are more powerful and enduring in nature. Using accurate cuts in a structure such as these means that manufacturers can product generally thinner, yet stronger products more resistant to breakage and cracking. This has resulted in reducing the amount of raw materials needed for production which leads to decreased costs and increased savings.

As technology continues to advance so it does for laser cutting machines as well in its evolution into more advanced and innovative improvements like virtually all industries. Today, these state-of-the-art peripherals have more flexibility and precision than ever before. In some cases, the machining may incorporate cutting heads capable of pivot to create bevel features in a part as well as multi-axis machines that facilitate turning-both perfectly suited for driving the aesthetics round plastic parts. Others are typically set up to adjust the height of your cutting tool automatically while it is working: either by preventing a collision with the surface, or by informing you that something shifted on.Ecosolidsurfacing.digitalinherits propertiesenvironment>();

In recent times, with the help of fiber optic cables (another innovation in a new dimension), cutting speeds have multiplied. Because they can cut into materials far more quickly than regular CO2 laser cutters, these machines are optimal for large-scale manufacturing applications specifically. In addition, using fiber optic cutting machines results in lesser maintenance which means more uptime and productivity.

Utilizing steel plate laser cutting machines enables manufacturers to produce high-quality end products, while achieving large time and cost reductions. They help in reducing manual labor and maximizing the use of raw material which results into a higher production with less resource utilization. What is more, laser cutting machines offer a high degree of precision in cut which empower them to generate small waste during the manufacturing process that highly contributes to their environmental friendly nature.

Overall, the steel plate laser cutting machine is revolutionizing manufacturing by offering new opportunities for customization, accuracy and affordability. In this day and age of rapidly advancing technology, these factory workers are only going to get more dexterous resulting in a highly advanced production process for the manufacturers. The huge ROI that will be in favor of your factory or small industry when you invest a Steel Plate Laser cutting machine

team in early stages of project, which is a continuous communication with customers, provide professional consulting advice and technical solutions to customize services, the transaction process, concentrate on every aspect of follow-up service experience, from the date of signing the contract, order processing, monitoring of the progress of production through rigorous manufacturing inspection, finally steel plate laser cutting machine of the whole procedure adjusting the management of the entire process .

are a top manufacturer laser equipment. place great emphasis on quality of products and their compliance. laser equipment has numerous internationally recognized certifications, including ISO QMS certifications, CE safety certificates other international certifications. These certificates ensure that laser equipment a popular choice in local steel plate laser cutting machine, but also that it is able be used international markets.

J Iangpin Technology a steel plate laser cutting machinelaser equipment which specializes production laser equipment. wide variety of laser equipment can easily be found to suit needs of various laser equipment.

are a leading manufacturer laser equipment with a robust research steel plate laser cutting machinedepartment, with wealth of knowledge in field. We can customize our products to meet demands of each customer. have 100+ professional patents, 100+ patents, plus 100+ certificates, are in more than 100 countries and regions throughout the world.