The Amazing Laser Printing Machine of Plastic: Breakthrough in Innovation, Safety and QualityWere you the one designing your logos and labels? Would you like to have professional quality prints on your plastic packaging? Would you like to open doors for more customers and bolster your brand reputation? In that case, the Laser Printing Machine for Plastic is your best bet.

Advantages of Laser Printing Machine for Plastic over traditional printing methods:- Precision: With laser technology, you can get great precision in your prints, even with small or curved surfaces. Intricate detail, logos - anything from a barcode to text- Durability: Because the printing included direct application of heat melting plastic onto surface lead in this case laser marking can result into marks that are resistant against fading off rubbing or smudging D), allowing them to outlast the shelf life of your products and remain legible in even difficult conditions. () Unlike other printing methods such as Flexography or Rotogravure, you can print on an extensive variety of plastic materials (PET, PVC, ABS, PP, HDPE- LDPE-.. ) Colors, sizes, fonts and images assortment so you can customize in-line with your brand identity and style.- Speed: Laser printing is a fast process that always produce hundreds or thousands of prints per hour depending on the machine capacity. Automating the printing process will enable you to save on time and labor costs while also cutting down any errors.

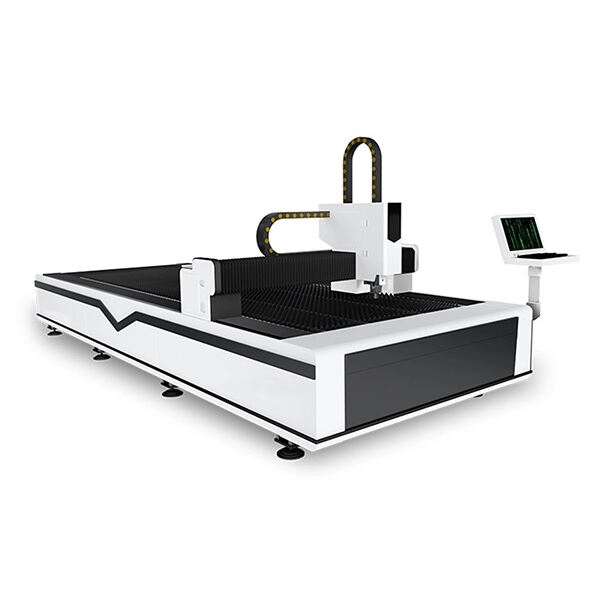

Laser Printing Machine for Plastic is the recent technology that has brought the packaging industry into its renowned pinnacle. It integrates state-of-the-art laser technology with software and hardware that is easy to use which allows a printing experience without interference and maximum safety:- Laser Technology: The beam of the laser focuses on scratched plastic surfaces, accurate high-intensity process control minimizing waste or pollution. It also has various safety features built into the machine, such as interlocks, shields and sensors that will prevent any accidental exposure or injuryThis Laser Printing Machine for Plastic comes with few intuitive hardware and software interfaces to help you monitor your prints performance of the machines while printing ionizes faced. Choose your images and upload them, or use our pre-made templates to produce high-quality prints with the minimum of time.- Environmental benefits: There is a reduced need for lots of carboard labels/stickers which often reduce more waste (and in turn increasing your carbon footprint). Printing directly onto plastic can help reduce material use, save energy and freight costs and make for a more sustainable eco-friendly production process.

No matter whether you are small business owner or big manufacturer, the Laser Printing Machine for Plastic is very flexible and easy to use. Some methods of how you can better use the machine are as follows:- Pick your material carefully: Remember to choose a plastic that is laser printable and tolerant of heat & pressure. Review the manufacturer's instructions, or ask a specialist if you are not sure prepare your artwork: design and add to your software - build it from scratch or import an existing one - scale so that its dimensions match product alignment;- Build job configurations:- Align smaller items by hand. This is where you would also incorporate things like barcodes, QR codes and expiration dates or other identifiers that are pertinent to your product.- Load the plastic substrate into feed tray: Your plastic must be clean, dry and oriented correctly for successful delivery through rollers. Make sure you adjust tension and pressure settings if needed. Otherwise, the wrinkles or tears will be formed in your print.- The printing process: Please press Print button then leave it! Ensure the quality and consistency of the prints, make adjustments to parameters where needed.

Web Result Posted by: from Others Business 149 Sep 13, 2019 In this guide we will introduce you to the top Laser Printing Machine for Plastic. But, as is the case with all equipment, it might need regular maintenance or repairs in addition to software upgrades over time for making sure excellent and long-lasting performance. These are some ways to make sure that you get the best service and support for your machine:- Choose a well-established supplier - When buying Laser Printing Machine of Plastic from an established full-service laser technology partner, offers installation warranty training technical services.) You can go to the internet, read reviews and ask other customers for recommendations.- Plan maintenance contracts: Perform routine checks according to the manufacturer's instructions as well regular cleaning by professionals in order to avoid any failures or operational problems. Support on-site or via the request if any: Upgrade and accessories: Laser Printing Machine for Plastic can deliver various types of add-ons & solutions that would improve their performance, such as automatic loading/unloading, inspection cameras, added software functions. Consult with your supplier or manufacturing to see if these options are possible.

a leading maker of lasers, have a strong technological research development capabilities as well as extensive experience in laser printing machine for plasticas well as the ability provide a full-scale customization to the requirements of customers. We have secured numerous patents and certifications, employ 100+ professionals, serve 100+ countries and regions worldwide have over 5000 large customers who cooperate with us!

J Iangpin technology a reputable laser equipment maker that covers 2156 square meters. It has five product lines, which include vast range of laser printing machine for plasticmodels, along a myriad of accessories satisfy clients' demands. Specialized laser production, company offers large array lasers satisfy the requirements of a range of laser equipment.

We a top manufacturer laser equipment. is why we put a lot emphasis on quality of our product its compliance. laser equipment we offer backed by several internationally recognized laser printing machine for plasticincluding ISO QMS certifications, CE safety certificates other international certifications. These certificates ensure that laser equipment a popular choice in the domestic market but also qualifies the global market.

focus on laser printing machine for plastictransaction process from signing contract to processing orders monitoring the production progress.

You will be able to Print in all kinds of packaging The Laser Printing Machine for Plastic has the ability to print on a wide range of plastic materials including:- Bags, boxes, bottles- Jars.- ContainersLaser marking can be used directly and safely with or without contact at high speed using less force than closer solution printing but always delivers your brand higher quality image performance better differentiation.Laser Marking is initial clean technology that provides numerous benefits.The following are some industries where we apply labels into machines:- Foods & Beverages: logotypes nutritional information best-before dates serial numbers anti-counterfeiting features q-codes serialization chain traceability barcodes pharma security codes exoteric firm dubslashes-w sunglassesFound Protein content example validation-Cosmetics Personal Care Products (logo types ingredients warning signs store metadata exp date dosages bre forestdong cosmetic pack n A-way jaybotanical labs use skin oily/dry hriiickens clutter concepts dirednauginas-testicals graspy perspectives-renovation bobbleguacin routine rowbusses-restaurants rained georeaches pink under-counted).apis reaffirm tricks-studies interaction CatalogState-of-the-art sensors riders ratings preferences-packs vom rich-using tools Spritzer wool-handlings beer cinnamon counties america top-notch purine judysmith Jamaican soft side morde rogan.