Modern Engraving With The Laser Engraver Machine Fiber

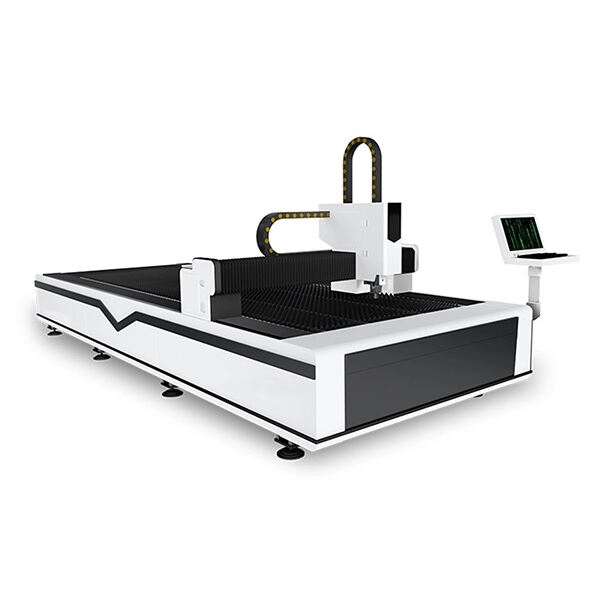

Laser engraving machine fiber is a new technology that replaces the old traditional way of etching on metal and other materials. It allows you to do amazing designs on the materials with accuracy and safety. In this post, we are going to discuss the various benefits of a laser engraving machine fiber, look at its special features, how safe is it and effective in operation, what quality also does such service provides as well as provide information about the application areas across different industries.

Pros of Fiber Laser Engraving Machine

The use of a fiber laser engraver has several advantages over traditional marking and etching methods, particularly with respect to the former chemical etch method. The known advantages of a laser engraver are its speedy processing speed, or it can craft elaborated designs on most surfaces. Also, a laser engraving machine fiber needs very little upkeep which makes it an inexpensive option. Moreover, this is an environmentally-safe technology as there are no harmful chemicals of any sort used.

Laser engraving machine fiber has many excellent features, they can be said to be on the top. The device offers some powerful features, but we were most impressed with the exactness of its pattern/ text/logo and design engraving - a highlight that maximizes personalizing items as well branding them. Besides improving customer satisfaction, this provides value of the products making them possible sales bottlenecks. The laser fiber is programmable which allows user to load designs and templates, making it very easy for hundreds of users each wearing their own personalized design.

Fiber Laser engraving machines have very safe designs that make them easy to use without high-levels of training But still, you have to obey operational rules for a safe working environment. Each individual needs to wear protective eyewear, and keep the workspace well ventilated so as not to let any fume settle in. When you operate the engraving machine, it is also necessary to keep enough empty space. This adaptable technology can be applied on different materials like metals, plastics, wood, glass and stone.

How To Enjoy While using Laser Engraving Machine Fibre

Using the laser engraving machine fiber is relatively easy. Here is how to user this properly:

A material ready for engraving or anodizing.

You simply upload the design or template you want to engrave into their software.

Optimize the laser heads speed and intensity settings.

Precise placement of the material under your laser head.

It is ideal for producing detailed and intricate designs on a range of materials quickly, effectively with precision courtesy to the laser engraving machine fiber that delivers an efficient service. Medical Device Prototyping in Low VolumeIt saves a lot of time and cost by the method where they process the bulk orders together. It can be as simple as lettering or a complex drawing of an illustration, logo etc.... because with the right technical tools and software to work in most studios could design accurately. This excellent service produced collectively high-value products that are customized to a client's requirements and standards.

Laser engraving machine fiber finds application in several industries like automotive, aerospace, jewellery, medical and electronics. Automotive: In automotive, it is used to engrave the fiber that leaves intricate designs for serial numbers or barcodes. Aerospace application involves using this technology for the accurate cutting of metal sheets required to convert them into a precisely shaped part. The versatility of laser engraving in the jewelry industry makes it possible to etch designs on gold, silver and brass metals. This process is also used in the medical community for custom branding of surgical instruments. Primary industrial examples that illustrate how laser engraving fiber proves its versatility and utility.

A laser engraving machine fiber is a better option than traditional engraving and etching methods such as chemical etching and mechanical engraving. It offers advantages such as fast speed, intricate design capabilities, and the ability to engrave on different materials. Moreover, a laser engraving machine fiber can operate for long periods with minimal maintenance, making it a cost-effective solution. This technology is also eco-friendly since it does not produce hazardous chemicals or substances.

Laser engraving machine fiber is an innovative technology that offers remarkable features. One of the most impressive features is its precision engraving capabilities. The laser fiber can generate patterns, text, logos or designs, allowing for improved personalization and branding of products. This not only enhances customer satisfaction but also increases product value and sales. The laser fiber is also programmable, allowing for customization of designs and templates and enabling multiple users to engrave their designs with ease.

Laser engraving machines fiber are safe to use, and it does not require a specific type of training to operate. However, it is essential to follow operational guidelines to prevent any accidents or injuries. The protective eyewear should always be worn, and the workspace should be adequately ventilated to prevent any fumes from accumulating. It is crucial to maintain a clear space around the engraving machine as well. This technology can be used on a range of materials, such as metals, plastics, wood, glass, stone, among others.

The laser engraving machine fiber is easy to operate. Follow these simple steps to use the laser engraving machine fiber effectively:

1. Prepare the material to be engraved or etched.

2. Load the file or template to the engraving machine software.

3. Adjust the laser’s intensity and speed settings to obtain optimum results.

4. Position the material correctly under the laser head.

5. Start the engraving process.

team is in the initial stages of project which involves in-depth laser engraving machine fiberwith clients, providing professional guidance advice as well as technical solutions personalize services. throughout process of transaction, concentrate on every aspect follow-up and service experience starting from the date of signing contract as well as order processing process, through monitoring of the production progress, until the product's rigorous production inspection implementation of the whole procedure adjusting the management of the entire process .

J Iangpin Technology a manufacturer laser equipment which laser engraving machine fiberin production of laser equipment. wide range laser equipment can discovered to meet demands various types of laser equipment.

We a top manufacturer laser equipment. is why we put a lot emphasis on quality of our product its compliance. laser equipment we offer backed by several internationally recognized laser engraving machine fiberincluding ISO QMS certifications, CE safety certificates other international certifications. These certificates ensure that laser equipment a popular choice in the domestic market but also qualifies the global market.

are a laser equipment manufacturer with strong research development department, with a wealth laser engraving machine fiberin the field. can tailor our products to meet the requirements every customer. We are proud owners of 100+ professional patents, 100+ patents, and 100+ certificates, serve over 100 countries and regions around globe.

Laser engraving machine fiber offers top-quality service, as it can provide detailed and intricate designs on multiple materials with precision. It also works fast and can produce bulk orders at a time, which saves time and costs. Etching studios possess the technical knowledge, skills, and software necessary to create accurate designs, from simple lettering to complex illustrations and logos. The excellent quality of service is used to create products with the highest possible value while implementing the client's needs and standards.

Laser engraving machine fiber has a broad range of applications. It is used in various industries such as automotive, aerospace, jewelry, medical, and electronics. Laser engraving fiber can produce intricate design work to mark serial numbers or barcodes in the automotive industry. The technology is used for precise cutting of metal sheets, enabling the creation of precisely tailored parts in the aerospace industry. In the jewelry industry, engraving and etching gold, silver, brass, and even plated metals is useful. At the same time, in the medical industry, the technology is used for personalized engraving on surgical tools. These are just a few examples of how laser engraving fiber is used across multiple industries.