Gems are brilliant and lively stones that glow boosting the elegance of jewelry crafted with them. Since they come in small nuggets, jewelers shape them into different shapes and sizes to add a final touch of beauty. However, thanks to revolutionary technology in the gemstone laser cutting machine it is possible.

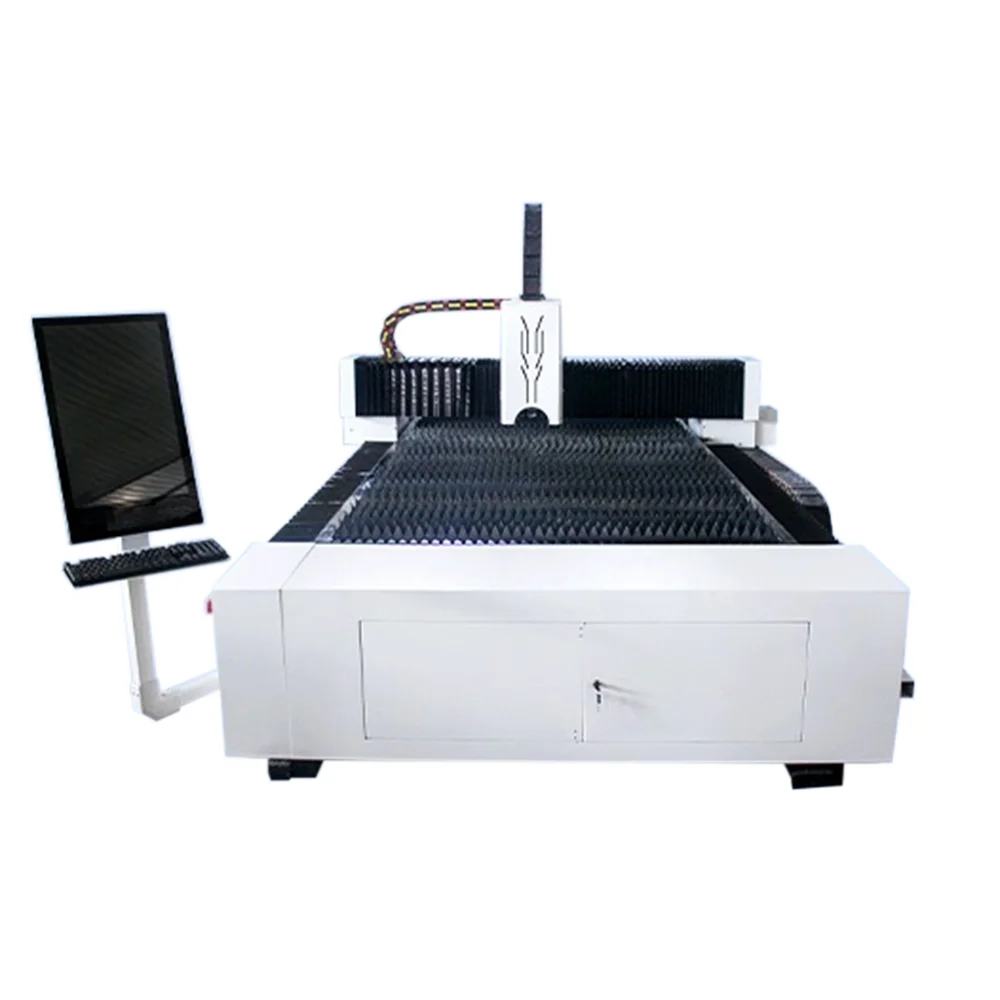

A gemstone laser cutting machine is a type of specialized equipment that cuts and forms gems by employing an innovative process known as the cut method. And all that precision, speed and capacity to slice through the smallest details of a stone even an eye above its necessary thickness make this machine stand out from other similar machines.

These various colors, shapes and sizes of gems attract people. A gemstone laser cutting machine allows jewelers to turn these captivating stones into one of a kind jewelry designs. The laser technology greatly influences to make most difficult gemstone cuts unlike past styles achievable using standard techniques.

Between the software and machines themselves, jewelers are able to customize exactly how their pieces turn out fulfilled with utmost precision in terms of shape. With this state of the art software, amazing new shapes and design creativity can be cut with much precision using the laser cutting machine in these precious gem stones.

Laser cutting machines use a concentrated beam of light to cut through various materials, such as metals and plastics. They are known for high speed, highly precise and capable of making complex designs. These designs are transformed into a machine tool path so that the laser cutting machine can impart high amount of heat energy required for precise cuts and shaping.

In the past, gemstones were cut with saws and other tools that may have not been as perfect or safe for gems. The gemstone laser cutting machine was introduced to combat this problem as it uses a high power laser beam, which cuts the gems accurately and without damaging adjoining material. That new capability gives jewelers the freedom to design stunning, one-of-a-kind gemstone creations that have never been possible before.

The art of cutting and shaping gemstones has been revolutionized by laser technology. From a jewelry perspective, the gemstone laser cutting machine has opened new doors and enabled jewelers to create unique precious stones such as art dial-like ruby dials that were unimaginable in the past. Its speed and precision bring together jewelers who cannot avoid utilizing this machine to add an attractive touch in jewelry designs.

To sum up, the gemstone laser cutting machine is a shortage of necklace making apparatus. It offers unparalleled accuracy, speed and the ability to create intricate pieces that make it a very important tool for any jeweler. For the first time ever, stunning gemstone cuts in designs will have a completely new dimension of lux owing to this radical machine artist.

are a top producer laser equipment. Therefore, place great emphasis the quality of product and its gemstone laser cutting machine. laser equipment we offer backed by numerous internationally recognized certificates including ISO quality management system certifications, CE safety certificates other international certifications. These certifications ensure that laser equipment highly regarded in local market, but it also meets the requirements the market in global markets.

J Iangpin technology a reputable laser equipment maker that covers 2156 square meters. It has five product lines, which include vast range of gemstone laser cutting machinemodels, along a myriad of accessories satisfy clients' demands. Specialized laser production, company offers large array lasers satisfy the requirements of a range of laser equipment.

are a laser equipment manufacturer with strong research development department, with a wealth gemstone laser cutting machinein the field. can tailor our products to meet the requirements every customer. We are proud owners of 100+ professional patents, 100+ patents, and 100+ certificates, serve over 100 countries and regions around globe.

focus on gemstone laser cutting machinetransaction process from signing contract to processing orders monitoring the production progress.