Technology is always evolving and with the production of goods in every industry turning faster, more efficiently and safer. Before that, the best innovation for last 50 years not only in steel but it is CO2 laser cutting technology and much more are on list. Hence these are the innovations, in some that provide numerous benefits which deemed to be a piece of apparatus indispensable condition for any firm striving or intended top to meet their production goals timely.

Steel cutting with steel laser cutterThis initial spark was ignited when CO2 lasers were first used for cutting and engraving in 1967.

Ultimately, there are many benefits to CO2 laser cutting steel which is why it has become the preferred alternative over traditional methods of laying. The standard first - of course - is that it's one of the most precise cutters you can buy, meaning your cuts are about as accurate as they're going to be. Not only does it allow the creation of designs that are far more specific and detailed than is possible using traditional methods for some industries, but additionally, in doing so these economies can be achieved at a fraction of what would otherwise... Abilities- additionally CO2 laser cutting is one of the most adaptable slicing techniques as it gives a yuge capacity to cut through many materials, from strong steel and titanium including fragile textures. This usage flexibility is key in differentiating and grows a business by starting production of new components or products - accompagnied increased income. In addition to this, CO2 laser cutting technology is speedier and more precise than conventional technologies making it easier for companies as they can now cater to orders in larger quantities at a much faster pace through these economical options.

Traditional methods of cutting metal can be dangerous, but newer versions such as the CO2 laser cutter for steel have advanced safety features that gear toward providing a safer working environment. This proprietary technology is combined with state-of-the-art safety features that protect operators against radiation and fire risks, creating a safe work environment. Moreover, the precision cutting is a tidier operation which shuts itself off without producing any smoke or fumes so you do not need to clean. This accurate cut along with speed is the reason CO2 laser cutting steel should be considered as essential to industrial businesses that need a boost in their production technique.

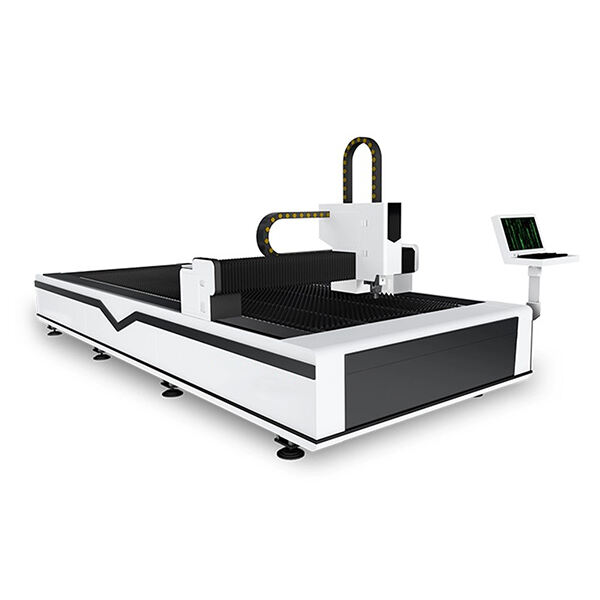

How to use CO2 Laser Cutting Steel [%year%] It is rather basic and easy to use the technology for cutting through materials. User just needs to load the laser, plug it in and send a power/speed parameter from list as how you need your new creation engraved. Laser tech then takes design specs and cuts away. Operators can make adjustments while the system is cutting because they have access to look at what's happening and adjust settings as needed.

When it comes to metal working, the single biggest factor is customer service. By some company, together with the current manufacturers of CO2 laser cutting steel technology as it provides superior quality service compared to traditional methods you may be using today when contacting for the first time surely satisfied and even increase revenues. When you understand that good is the enemy of great, and as we all know - long term customer satisfaction starts with a quality end-product.

Steel CO2 Laser Cutting Is Versatile With its wide range of applications, the flexibility and adaptability are such that it can create customized solutions for any type of business. This latest technology facilitates businesses to meet various production needs like tooling, machine parts, decorative items and prototypes simply in minutes.

Final Thoughts A CO2 laser cutting machine and steel are truly a match made in heaven - at least if you want to benefit from the most accurate, fast today available cut methods that will not compromise on safety of your employees. Laser cutting growth Technology for CO2 laser cutter Laser engraver software has long been at the forefront of pushing how businesses improve production processes to deliver products expected by an ever demanding consumer base.

are a top producer laser equipment. Therefore, place great emphasis the quality of product and its co2 laser cutting steel. laser equipment we offer backed by numerous internationally recognized certificates including ISO quality management system certifications, CE safety certificates other international certifications. These certifications ensure that laser equipment highly regarded in local market, but it also meets the requirements the market in global markets.

a leading maker of lasers, have a strong technological research development capabilities and rich expertise the field We able to provide a full-scale customization to particular requirements of customers. We have co2 laser cutting steelnumerous patents and certificates, have more than 100 professionals, cover 100+ regions countries around the world, have 5000+ large customers who cooperate with us!

team is in beginning stages of project which co2 laser cutting steelin-depth communications with clients provide professional guidance advice as well as technical solutions for customizing services. during transaction process we focus each link to follow-up as well as service experience, from signing of the contract, order processing, monitoring of the progress of production through the rigorous factory inspection, and execution of the whole process of fine-tuning management of the entire process .

J Iangpin Technology a manufacturer laser equipment that specializes manufacturing laser equipment. wide range co2 laser cutting steel equipment can be found suit the needs different types laser equipment.