One the technology side, few types have shaped recent craft trends as much as 3D laser engravers in modern craftsmanship. They are the powerful machines that artisans use to meld together an idea and reality - each a wonder of speed, function, precision - changing how artists enhance imagination while pushing creativity toward new boundaries. In this article, we are going to explore the layers of what makes 3D laser engraving such a game changing technology for artisanal work and customization as well it being more sustainable and advancing multiple industries in different ways.

Historically, engraving has been a very laborious process that took many hours of tedious handwork to produce intricate designs in material. The 3D laser engravers considerably changed this act though. Not only do these tools expedite the process, but they also raise what is possible in terms of detail. This integration has made it incredibly simple for craftsmen to translate even the most complex visions onto a variety of materials: from fragile glass to indestructible metals, with an accuracy that previously was impossible. Striking the perfect balance of technology and tradition, this unique union keeps intact the basic nature of artisan work, updating it with advanced methods.

A relief that 3D laser engraving can achieve the size and depth no any other technology. Regular 2D engraving is done on the surface, meaning that it does not have any additional depth than its flat layer with a design. With 3D laser printing we can create volume shapes and textures which physically are able to touch as well as visually perceive from afar - making it deeper experience for both our sight and feeling when touching an object. This particular dimensionality allows for a myriad of amazing things artists could do to push realism and storytelling in their art. It can range anything from imitating the texture of tree bark onto a wood sculpture or engraving insanely tiny details landscapes on small metal pendants; 3D laser engravers have their own ways to catch every single subtlety of gradients.

Ultimately, 3D laser engraving meets the need of individualization which has become a cornerstone in modern consumer preferences. Being digital they can be manipulated and personalized easily, allowing the artisans to respond quickly and accurately to a clients specific needs. This ranges from monogramming jewelry to engraving personal messages on a gift, the customizing procedure is made easy using devices and without taking more time but only increasing with quality and speed. This not only improves customer satisfaction but also adds to the competitive edge of craftsmen who can serve up special efforts in today's market environment.

In a time when sustainability is at the forefront of all local and international sectors, 3D laser engraving shines as part of that collective movement to fix worldwide challenges. And laser engraving is cleaner and safer compared to traditional etching methods, which are often wasteful or contain harmful chemicals. No waste is produced and it eliminates the need to use toxic chemicals so this becomes an ecological alternative. In addition, the efficiency of these machines means less energy use per item produced, which also makes artisanal production's carbon footprint slip away. 3D laser engraving could be the future of crafting As we all want to go greener, in our fight for a more sustainable lifestyle.

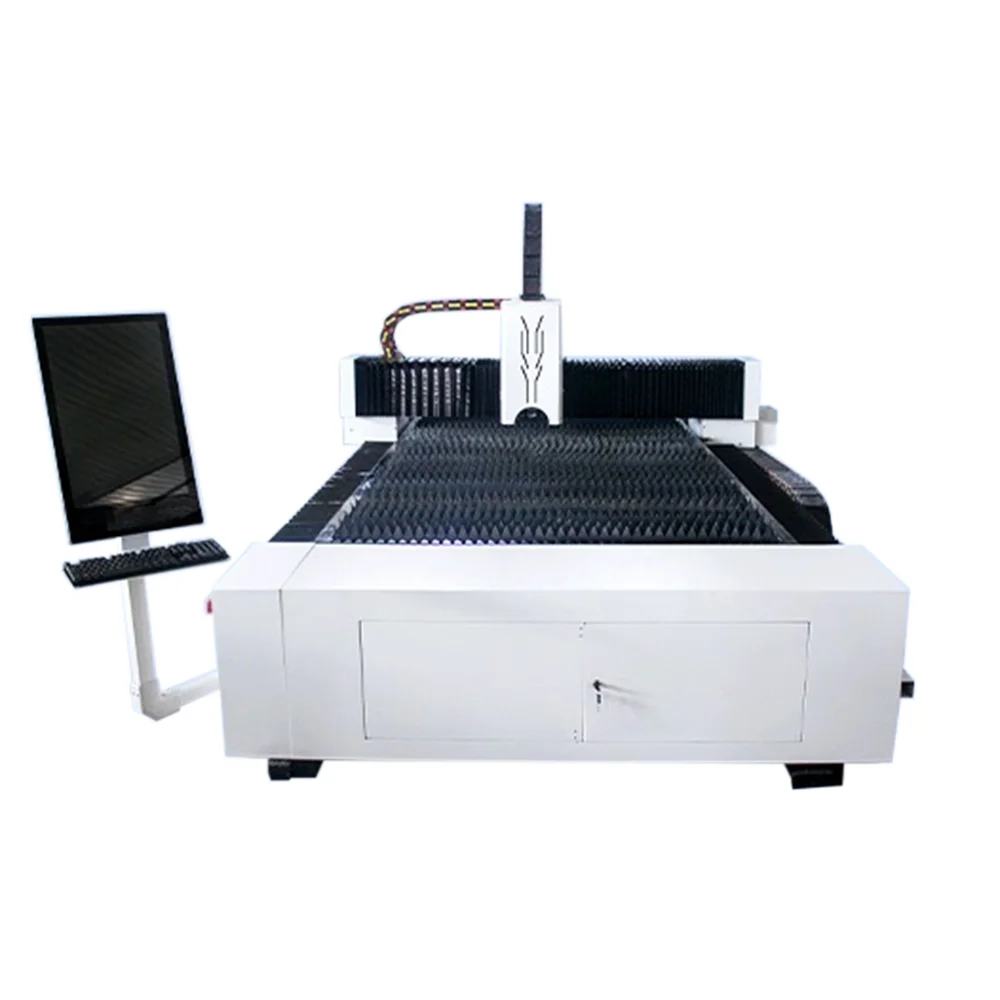

focus on the entire process transaction from signing contract ordering processing 3d laser engravermanufacturing progress.

J Iangpin Technology a manufacturer laser equipment that specializes manufacturing laser equipment. wide range 3d laser engraver equipment can be found suit the needs different types laser equipment.

a leading maker of lasers, have a strong technological research development capabilities as well as extensive experience in 3d laser engraveras well as the ability provide a full-scale customization to the requirements of customers. We have secured numerous patents and certifications, employ 100+ professionals, serve 100+ countries and regions worldwide have over 5000 large customers who cooperate with us!

a top manufacturer of laser equipment, attach great importance product quality and conformity, hold an array internationally recognized certifications, 3d laser engraverbut limited to ISO Quality Management System certification, CE safety certification other international certificates. These guarantee that our laser equipment is not just acknowledged the market of own, but also has legal and compliant qualification for access to the international market.

More than just paint and glitter, 3D laser engraving use extends well into more modernized fields. These devices also support exact marking and identification of parts in manufacturing, which allows for better traceability and QC efforts. They provide the ability to design micro-scale features necessary for cutting-edge surgical instruments in healthcare. In architecture as well in 3D design, Models and prototypes can be produced both of which are a physical representation of digital concepts using this technology. It is this versatility that demonstrates its potential to disrupt not just one, but many a sector and transform into something of a Swiss army knife in the era of digital transformation.

Overall the effect of 3D laser engraver on artisanal handicraft is considerable, which combines ancient tradition with modern tech. The capabilities of metal 3D printers are second to none in terms of accuracy and sustainability, making them suitable for a variety of industries. For we are just beginning to scratch the surface of what this technology can do and it is soon becoming abundantly clear that 3D laser engraving reaches far beyond a mere instrument, provoking artistic advancement in our contemporary society.